Iranian Firm Manufactures Modular 3D Bioprinter

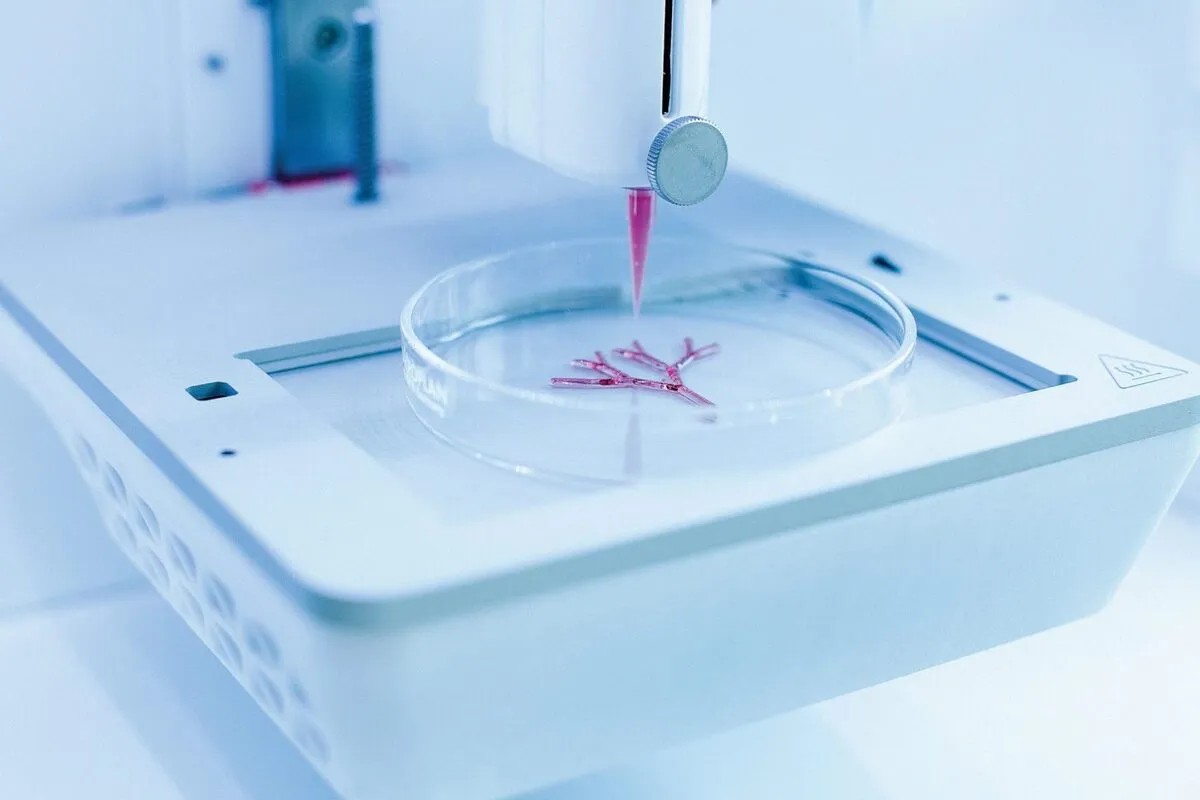

“This advanced technology has created a significant change in treatment methods and improving the quality of life. The modern 3D bioprinters are known as the pioneers of this area, and their work process includes the use of biological inks that are stored in special cartridges and produce the structures needed by the body through needles embedded on the platform,” said Mahmoud A’zami, the managing director of the knowledge-based company.

“Our company’s modular 3D bioprinter is made by metal sheeting method, and in addition to its beautiful appearance, it offers user-friendly performance and is compatible with complex print mechanisms,” he added.

“One of the basic challenges in designing this printer is the need for changing various extruders, and now, thanks to the use of modern mechanisms, this process can be easily done and allows users to apply the device without wasting time,” A’zami said.

3D bioprinting is an additive manufacturing process that uses bioinks to print living cells developing structures layer-by-layer which imitate the behavior and structures of natural tissues. Bioinks, that are used as a material in bioprinting, are made of natural or synthetic biomaterials that can be mixed with living cells.

The technology and bioprinted structures enable researchers to study functions of the human body in vitro. 3D bioprinted structures are more biologically relevant compared to in vitro studies performed in 2D.

Mostly, 3D bioprinting can be used for several biological applications in the fields of tissue engineering, bioengineering and materials science. The technology is also increasingly used for pharmaceutical development and drug validation. Clinical settings such as 3D printed skin and bone grafts, implants and even full 3D printed organs are currently at the center of bioprinting research.

4155/v