Iranian Company Manufactures Komax Machine to Process Different Wires

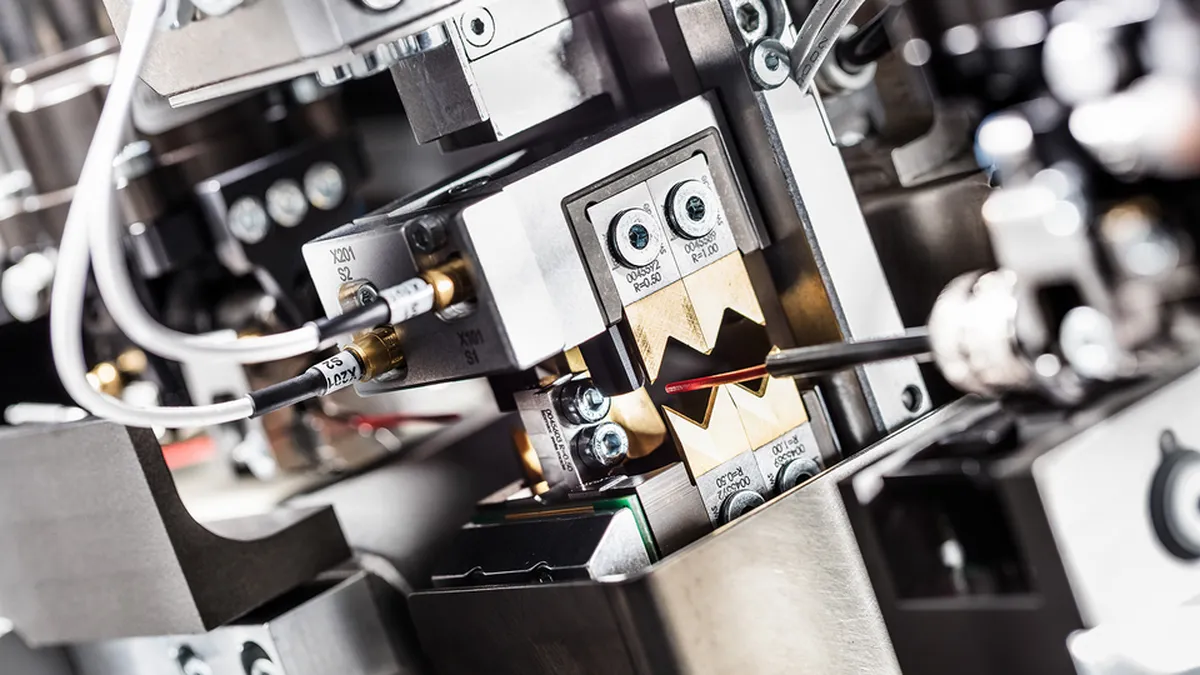

“The connectors in this machine cut wires used in different cars with various dimensions and sizes, and as a result, the connectors are connected to each other and form access,” Morteza Marzbani, a master's student in mechanical engineering at Islamic Azad University’s Mashhad branch and the company's managing director told ANA on the sidelines of Asr-e Omid event in the Northwestern city of Tabriz.

“The Komax machine cuts the wires in different cars to the same size and presses the connectors together,” he added.

“We tried to use robotics and artificial intelligence in the company. Now, by optimization, costs will be reduced and time will be saved," Marzbani said.

In a relevant development in 2024, electronics department specialists of an Iranian knowledge-based company succeeded in designing and producing a car wiring harness test device by using Python artificial intelligence technology.

“A process exists in the production line of car parts manufacturing and design factories which is called car wiring harness test to check if all wires assembled by human or machine are functionally tested,” Amin Keyqobad, the managing director of the knowledge-based firm, told ANA.

“The testing of these strings of wires is usually conducted by human forces, which, in addition to being dangerous for a human's life, is very time-consuming since nearly 6,000 pixelated strings of wires should be opened by a human operator and then checked one by one,” he added.

“This device has been made by using Python artificial intelligence or Python AI, and it tests a string of wires every three milliseconds. A central computer connected to the device is mounted on a wire test table, which shows the wire connection map on the monitor. When the AI detects that a wire is not working properly, a number of red lines will appear on the monitor,” Keyqobad explained.

4155/v