Iran Uses Smart Robots to Combat Microdust in Power Grid System

“In certain sectors of the electricity and water industry that face difficult working conditions like high temperatures in power plants or equipment repairs in remote areas, the use of robots can be very effective,” said Dolat Jamshidi, the head of the Center for Innovation and Development of Information Technology, Communications and Security at Niroo Research Institute.

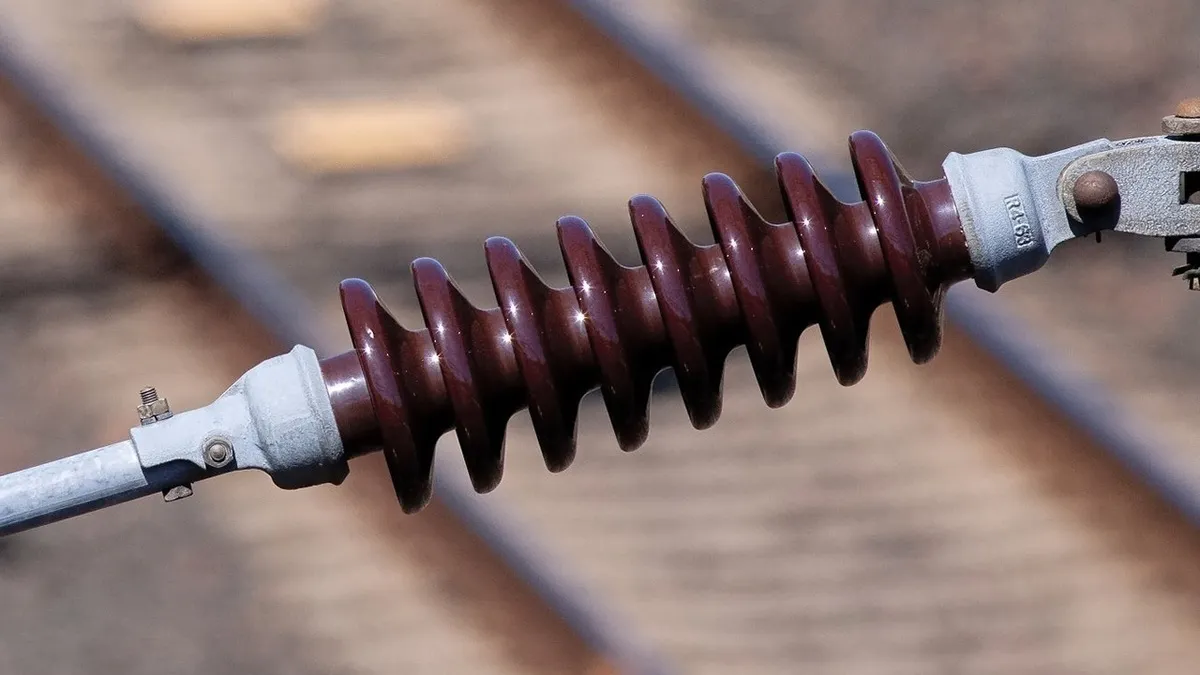

“At present, robots are used to monitor power transmission and distribution lines. Robots have also been used to wash insulators that are contaminated by microdust and disrupt system performance,” he added.

“Iranian knowledge-based companies, with the necessary technical know-how, are developing and producing these robots. The NRI also plays a scientific and technological support role in this process,” Jamshidi said.

In a relevant development in January, Iranian experts at a knowledge-based company had also managed to manufacture RTV silicone nanocoatings to protect the high voltage insulators from pollution and humidity and increase their lifespan.

“The product we have made is RTV silicone coatings, which are mainly used in the power industry. These coatings are applied as self-cleaning, hydrophobic and anti-fouling coatings on the equipment,” said Monireh Taqvayee, the managing director of the company.

“Insulators are made of silicone, glass and ceramic. Silicone insulators have a short lifespan but they are suitable for polluted environments. Ceramic and glass insulators enjoy high strength but they quickly face problems in polluted environments,” she added.

“In this product, we used the advantage of both parts by creating a silicon nanocoating on the surface of the insulators,” Taqvayee stated.

Noting that the silicone nanocoating with hydrophobic properties protects insulator against harsh environment and pollution, she said, “This coating can remain on the surface of ceramic and glass insulators for years, and even after damage which is caused by power outages, re-coating the insulator is possible.”

“We have launched the production line of this product, which has the capacity to produce 300 tons per year,” Taqvayee said, adding that the regional power companies, petrochemicals, steel and cement factories, and companies facing fine dust problems are the customers of this product.

4155/v