Reducing Environmental Pollution with Iran-Made Oxidative Desulfurization Catalysts

“Oxidative desulfurization is an effective method for removing sulfur compounds present in various oil fractions. This method can also be used to regenerate sodium hydroxide (used caustic stream) used in MERAX units that use caustic to decrease the concentration of sulfur and mercaptans present in hydrocarbon fractions,” said Hassan Navayee Alvar, the managing director of the knowledge-based company.

He explained that removing mercaptan compounds from various oil fractions and crude oil is possible by using the DMD process, which involves several steps.

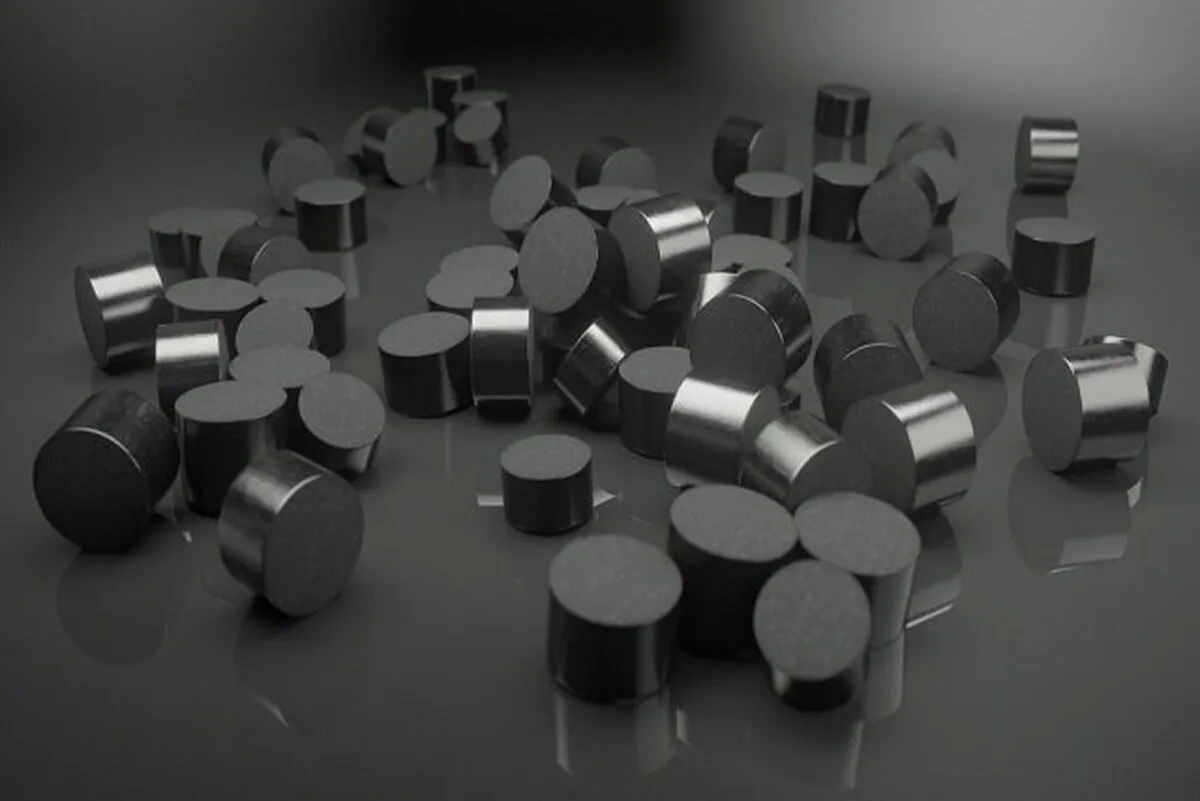

“The technical know-how of producing this catalyst has been developed for the first time in Iran as a heterogeneous catalyst. The sample of this catalyst was produced in our plant and its performance was assessed through numerous tests on a laboratory scale and a continuous laboratory pilot and with feedstock from various refineries,” Navayee Alvar said.

“This catalyst, which has undergone its laboratory and pilot stages using feedstock from Shiraz and Tehran refineries, enjoys the potential to be commercialized in refineries, mini refineries and related centers, given the volume of fuel oil stored in Iran and the problem of providing low-sulfur fuel suitable for related uses, including shipping fuel,” he underlined.

Harvesting clean energy from fuel feedstocks is of paramount significance in the field of environmental science. In this dynamic area, desulfurization provides a valuable contribution by eliminating sulfur compounds from fuel feedstocks to ensure the utilization of fuels without the emission of toxic sulfur oxides (SOx gases).

Nonetheless, the inadequacy of the current industrial technique (hydrodesulfurization, HDS) in the removal of refractory sulfur (RS) compounds and the stringent rules imposed on the fuel sulfur level have kindled research on other desulfurization methods like oxidative desulfurization (ODS). With the capacity of eliminating RS compounds under mild conditions, ODS is endorsed as a suitable replacement or complementary to HDS. ODS, in general, consists of two steps of oxidation and extraction.

The oxidation of sulfur compounds is carried out using a suitable catalyst (hereafter termed as an ODS catalyst) in the presence of an oxidant. Choosing a suitable ODS catalyst for industrial applications is still a quest among the various types of catalysts reported so far.

4155/v