Iranian Company Increases Life of Brake Pads by Nanocoating

“Our knowledge-based company has used nano materials in various parts to improve the durability and performance of its products,” said Qassemi, the R&D manager of the knowledge-based Pars Pad company.

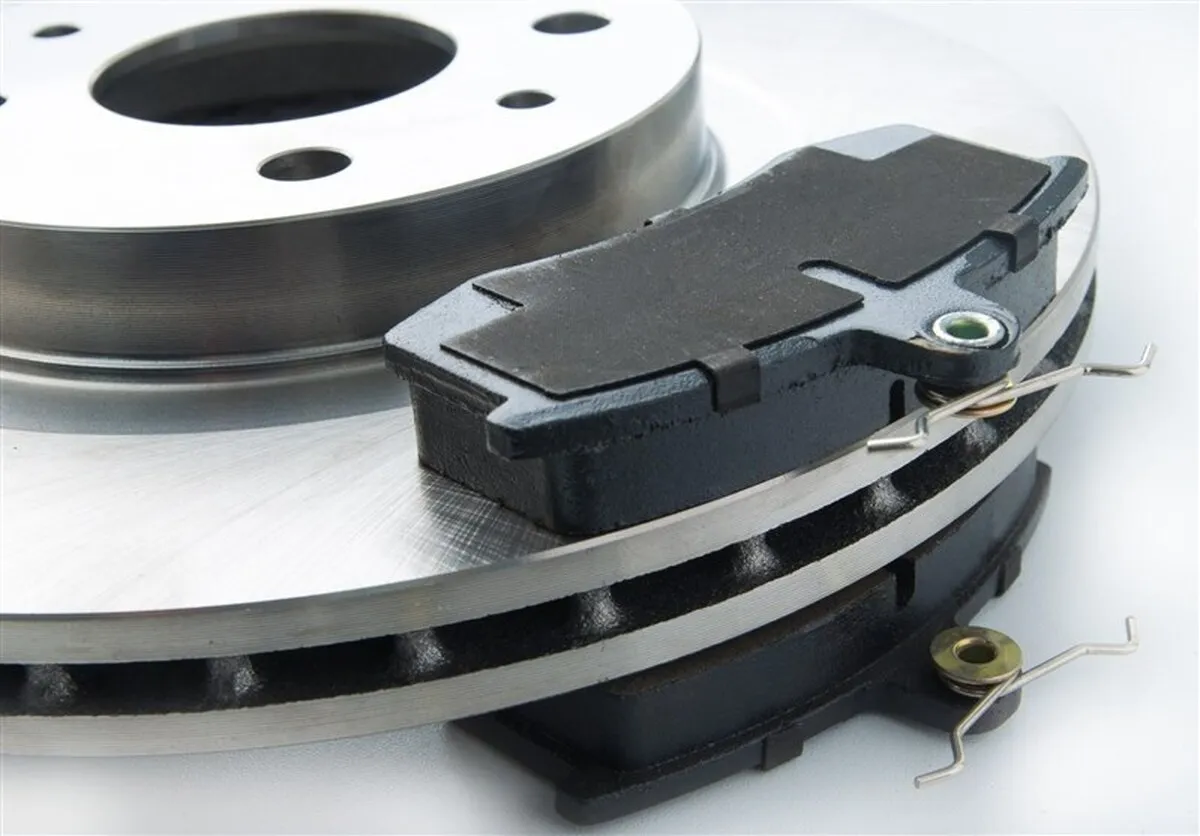

The first area of application of the technology used in our products was in the coating of brake pads. The use of nano paints and coatings has prevented the metal part underneath or backplate of the pad from corroding in the event of a brake fluid or engine oil leak and the pad comes into contact with wet environments, and the formation of looseness in the piston is prevented,” he added.

Qassemi explained that in addition to the outer coating, a set of nano additives has also been used in the composition of the brake pad, adding, “In light vehicles weighing approximately one and a half tons and also in motorcycles, the life of the brake pad, which was previously defined as about 20,000 kilometers, has increased to 30,000 kilometers after the use of nano additives, and this increase in life has been documented in urban and suburban vehicles.”

“At present, field tests and trials are being conducted to evaluate the performance of nano pads in heavy vehicles and trucks,” he noted.

In a relevant development in 2023, Iranian researchers at a knowledge-based company in Iran had been able to improve the durability of compressors in oil and gas industry by up to 300 times using ultra-hard coating equipment.

Hassan Jahdi, the managing director of the Iranian technological company, said that producing ultra-hard coating equipment using the PVD method is the main field of activity of their company. He pointed to the importance of using coatings in the industry, saying, "In some parts of compressors, the use of coating can increase the durability of the parts significantly."

“Nanocoating technology has become really popular in industry that it is known as a mother industry. The reason for this is the role that coatings play in an industrial product. In various industries, we are faced with parts that have different mechanical properties, durablity, wear and corrosion resistance, and we can apply special properties to the surface through coatings to increase the lifespan of the parts,” Jahdi said.

“In the oil and gas industry, we use nano-coating to reduce corrosion and bring it under control,” adding, “Oil extraction and exploitation take place in special conditions. This industry has a very corrosive working condition. But if coating is used, it can help reduce rate of corrosion.”

“In gas turbocompressors, coating is applied to control the wear and corrosion. It is considered a high-tech technology in the world. Increasing the efficiency and lifespan of these compressor parts, which are usually very expensive and important parts, is one of the applications of coating,” the engineer explained more.

“These uncoated parts lack proper performance, but with the development of coatings and the entry of nanotechnology into the field of coatings, this role has become more important as time passes, so that many companies producing these parts focus a major part of their research and development program on the coating.”

4155/v