Iranian Company Produces Nano-Bumpers to Reduce Road Accident Injuries

The product can be used as a bumper to reduce accident injuries, it can also be used in other industries like construction, urban furniture, and sports equipment production.

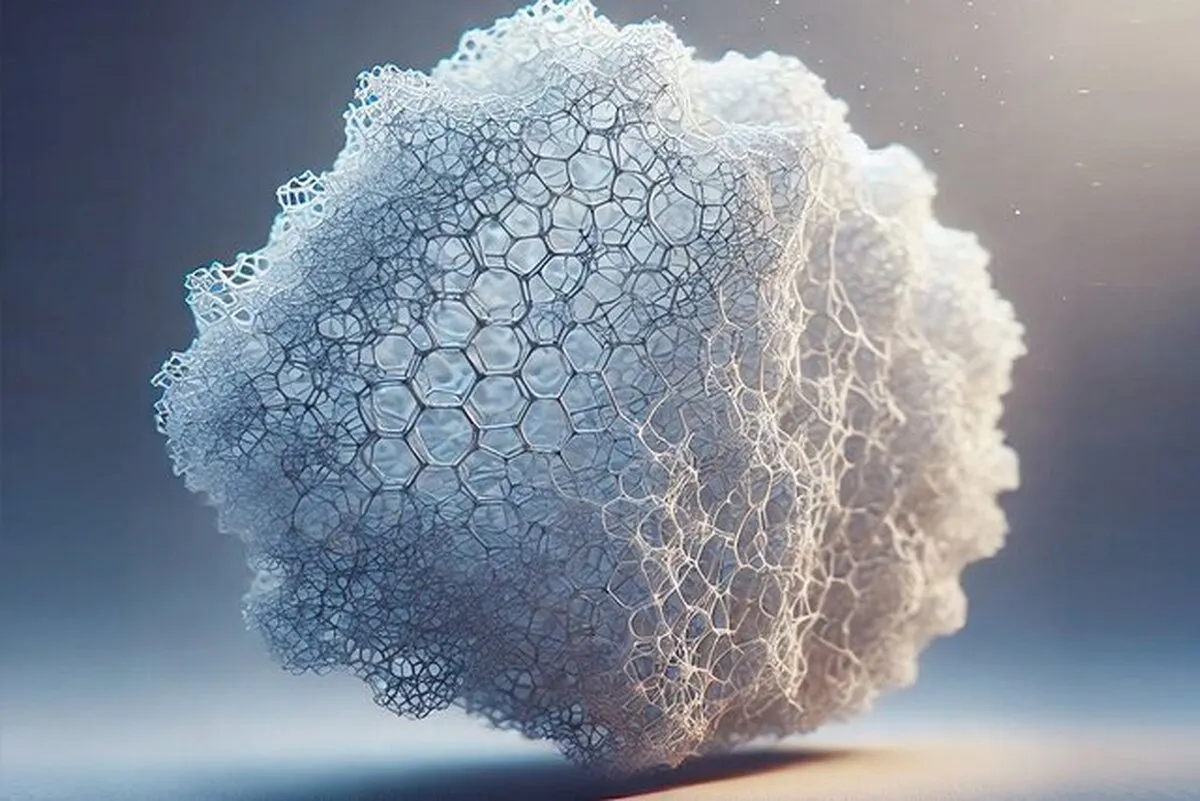

“Using nanotechnology, we have succeeded in producing resistant and shock-absorbing polymer granules that can be effective in reducing injuries caused by accidents. These foams absorb the energy from the impact and prevent it from being transferred to the passengers,” said Esma’eel Nouri, the managing director of the company.

Noting that these granules are placed under high pressure and temperature in reactor devices, and a saturation process is performed on them, he said, “Then, with a sudden drop in pressure, they are transformed into light and resistant foams. The final molding and curing of these foams is also done at customer sites so that the parts are ready to be installed on the vehicle.”

“This material is also used in the production of shock absorbers for domestic vehicles. It is also used in the packaging of temperature-sensitive drugs, as it prevents thermal changes and prevents the drug from spoiling during transportation,” Nouri said.

In a relevant development in 2023, Iranian researchers at a nanotechnology company had also managed to produce strong vehicle break pad adhesive which shows high thermal resistance.

‘Polymer Pishrafteh Amirkabir’ company has succeeded in producing the brake pad adhesive in which nanoparticles are used to improve quality.

"Pad adhesive is used in the production line of brake pads for light and heavy vehicles whose task is to connect the two lower parts and the upper layer of the pad to each other,” said Mohammad Alizadeh, one of the founders of the company.

“We used nanoparticles to improve the thermal properties of this adhesive. The pad is a piece which is constantly subjected to friction and high temperature,” he added.

Noting that the addition of nanoparticles to the adhesive increased the thermal resistance of the pad so that it shows more resistance than normal pads in the hot shear test, Alizadeh said, “At present, the adhesive is being produced on an industrial scale of one ton per month.”

4155/v