Iranian Firm Manufactures Machine Condition Monitoring for Rotating Machinery

The 3500-rotating machine condition monitoring was indigenized by the engineers at the Iranian knowledge-based company, supported by the Iranian Vice-Presidency for Science, Technology and Knowledge-Based Economy in the form of first-time production and has been put into operation in the 2nd and 12th refineries of the South Pars Gas Complex.

“As an advanced and comprehensive system, this system is responsible for continuously monitoring the temperature, vibration, and speed of machinery, and by utilizing 60 monitoring cards and peripheral devices, it helps to facilitate industrial operations and provides optimal protection for machinery,” said Seyed Badr ol-Din Moayyedi, the managing director of the knowledge-based company.

He described dynamic dual monitoring as one of the features of the product, and said, "This capability allows the system to simultaneously measure absolute and relative vibrations, which provides a more comprehensive understanding of machinery behavior and helps identify changes and potential problems."

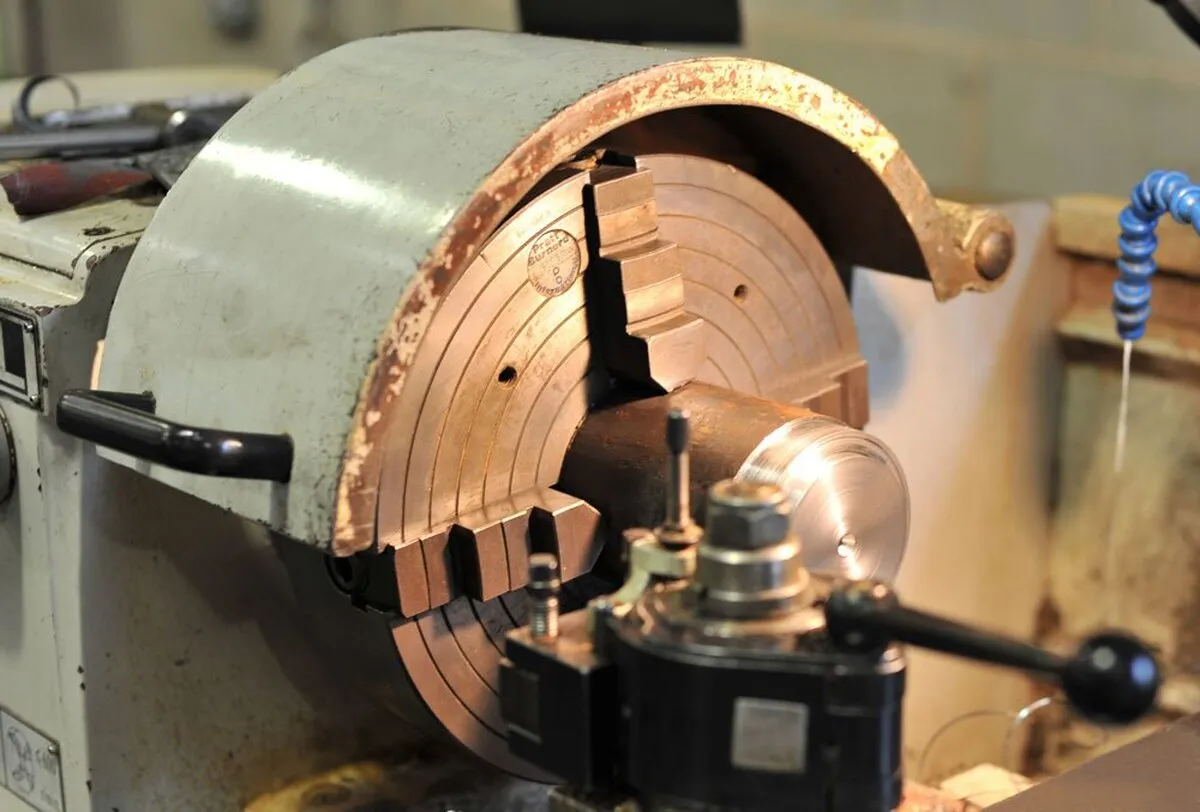

Machine Condition Monitoring is a critical component of a predictive maintenance program, and is usually carried out on rotating equipment and other machinery including pumps, electric motors and compressors.

Rotating machinery is often critical to the running of processing plants, and their reliability must be guaranteed at all times.

Machine Condition Monitoring tracks the working condition of a plant and machinery. In order to identify levels of change including decreasing performance, a developing fault, or failure. These faults, if undetected, or detected too late, can have disastrous consequences. The premise of Machine Condition Monitoring therefore, is that maintenance should only be carried out when we detect these levels of change. Therefore avoiding unnecessary downtime and cost.

4155/v