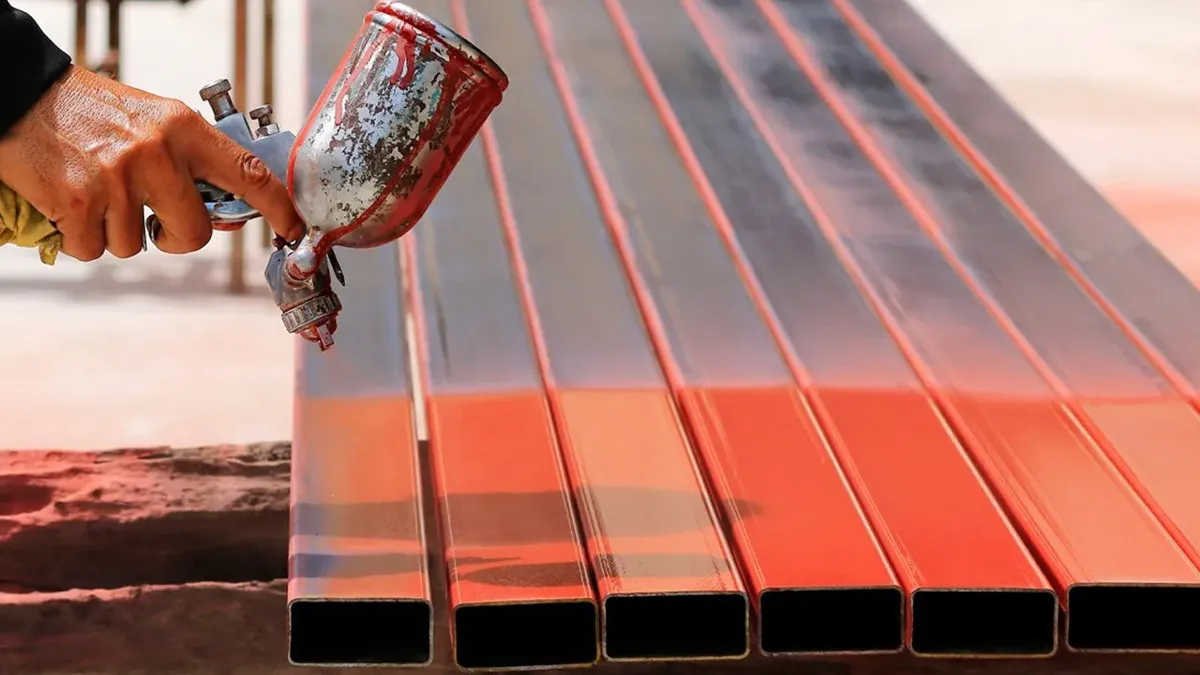

Iran-Made Nano-Based Alkyd Paint Fights Corrosion in Oil, Shipbuilding Industries

The product, which has successfully passed the international standard tests, can be used as a sustainable and cost-effective coating in various industries from construction and petrochemicals to shipbuilding and automotive.

A salt spray test was conducted based on the ASTM B117 standard on samples painted with this product. In this test, the control sample, which had no color, blistered and showed signs of corrosion after only 48 hours, while the samples painted with nano-paint did not show any blistering even after 240 hours.

Also, the corrosion intensity in the unpainted samples was much higher than the samples coated with nano-alkyd paint.

The results showed that the product of Nano Arisa Poshesh company has been able to provide very good anti-corrosion performance. Other features of this paint include high resistance to corrosion, good adhesion to various surfaces, and stability against harsh environmental conditions.

Such technical characteristics have made this product suitable not only for the construction industry, but also for strategic industrial areas. Using this paint in petrochemical and oil refineries, shipbuilding and marine industries, automotive and even pipelines transporting metal materials can significantly reduce the costs of corrosion.

In a relevant development in July, Iranian engineers had also used nanotechnology to produce a polyurethane-based metallic paint that, in addition to creating a unique effect, can be applied to a variety of surfaces without the need for special skills.

The special paints are a subcategory of advanced polyurethane-based paints that are produced by using optimized formulations in two models of air-dry and oven-dry. When nanoparticles are used in these paints, fine and uniform cracks are formed after application to the surface, giving the final surface a stone, leathery or textured appearance which is an effect rarely seen in decorative coatings or paints.

In common polyurethane paints, the surface only has a uniform appearance after drying. However, this technological company has created a revolution in the final appearance of this paint by adding special nanoparticles to the base composition. These nanoparticles cause different physical behavior when the paint dries, resulting in fine but regular cracks that are both aesthetically pleasing and help the paint to be better visible in indoor environments.

One of the key advantages of this crack-causing paint is its ease of application, even for non-professionals. This product does not require special skills, complex equipment or previous experience working with decorative paints, and it is enough to use simple tools like a spatula, brush or roller to achieve a professional result. Also, this paint can be applied with a variety of paint sprayers, including air and airless pumps and even multi-color devices. Due to its special formulation and stable structure, this paint also provides easy repair over time. In the event of a line or surface damage, only that spot can be repaired without the need to paint the entire surface.

Another practical feature of this product is its high ability to cover surface defects. The cracks created by the presence of nanoparticles help to visually erase surface irregularities and imperfections to a large extent. This crack-causing paint can also be applied to a variety of surfaces, including wood, metal, MDF, plaster walls, and even paintable plastics. The important point is that there is no need to use a special primer or base coat to apply it to many of these surfaces.

4155/v