Iran-Made Shock Absorber Tank Minimizes Pressure in Water, Oil Transmission Pipes

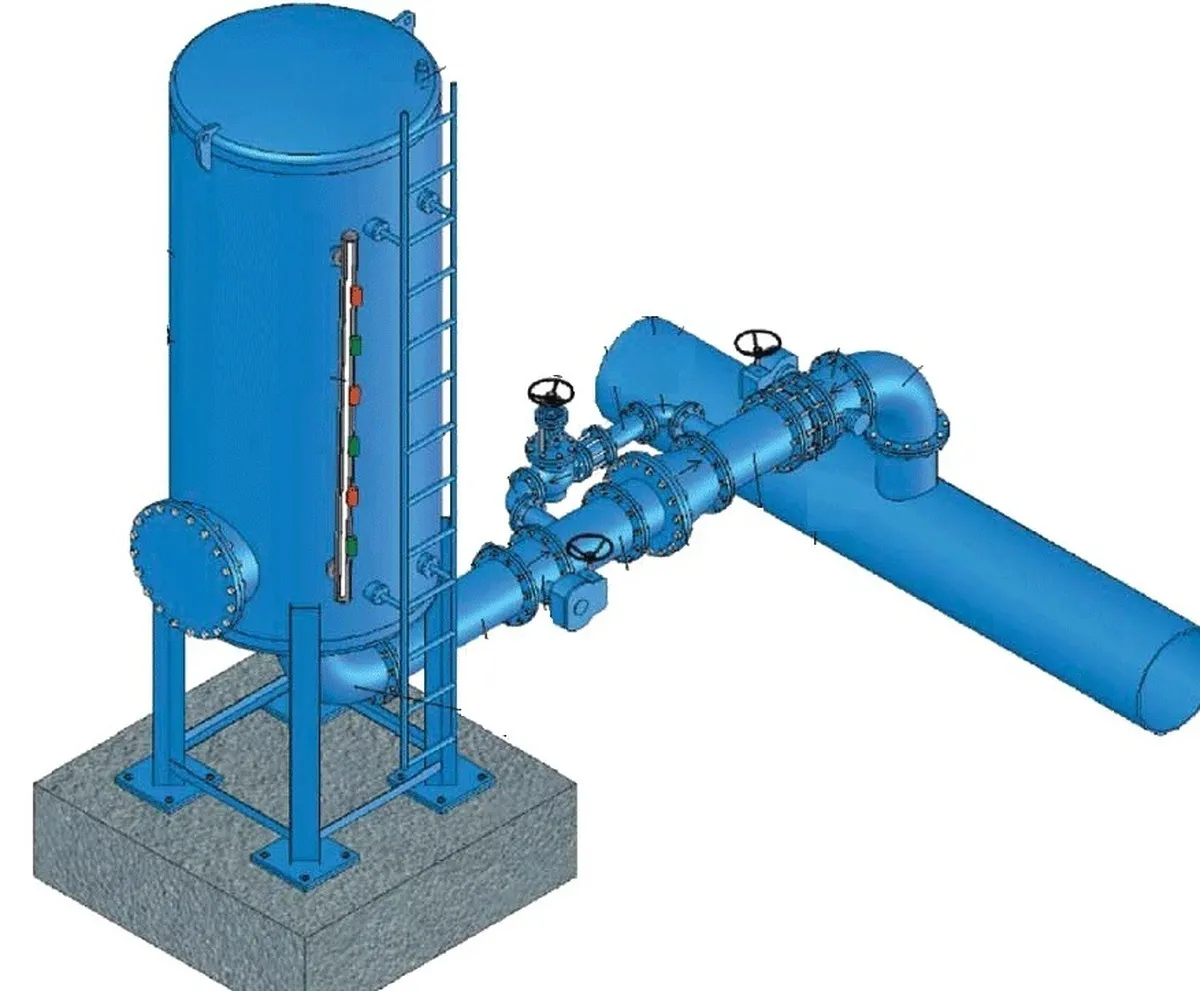

“Shock absorber tank is one of the most important equipment in water, oil and pumping systems transmission lines, which minimizes the impacts of reducing or increasing pressure in pipelines under pressure and prevents the phenomenon of ram impact,” said Hamid Abedinzadegan Abdi, the managing director of the knowledge-based company.

“In other words, the shock absorber is put under pressure in the way of fluid transmission lines, so that in case of pressure increase, it acts as a storage tank and when the pressure decreases, it acts as a reservoir and power source,” he added.

Noting that an increase or decrease in pressure in water, oil, etc. transmission lines causes sudden waves, which are known as ram shocks, Abedinzadegan Abdi said, “The phenomenon of ram impact depends on various factors like changes in flow rate and pressure and speed of fluid transfer.

Considering the dangers and serious damages caused by the phenomenon of ram impact to the body of pipes and fluid transfer facilities, the shock absorber tank can be an effective factor in eliminating this phenomenon.”

In a relevant development in May, an Iranian knowledge-based firm designed and produced smart pipeline inspection gauges for oil and gas pipelines to save the country millions of dollars by meeting domestic needs.

“About 100,000 kilometers of high-pressure pipelines have been built in the country to transfer oil, gas, and products such as gasoline and diesel, and according to international standards, these lines must be inspected every five years by means of smart pigs. Now, such a thing is produced inside the country,” Saeed Nazar, the managing director of the Iranian knowledge-based company said.

“The smart pigging instrument is able to identify all the defects in the transmission pipelines. Until now, these inspections were carried out through foreign companies, which could have transferred information about Iran’s pipeline network to outside the country,” he said.

“We were able to locally produce this device and its electronic, mechanical and data interpretation parts and specialized software were also developed in this company,” Nazar said.

“This device has been tested in several gas and liquid products transmission lines and its approvals have been issued by the Ministry of Petroleum,” added the managing director of the knowledge based company.

Saying that the device can be considered as a robot, he pointed out, "When this system is placed inside the transmission pipe, without the need for cutting fluid or gas, it starts inspecting with the same amount of pressure inside the pipeline.”

According to him, this device can identify all the corrosion inside, wall and outside the transmission lines with one scan up to 250 km.

4155/v