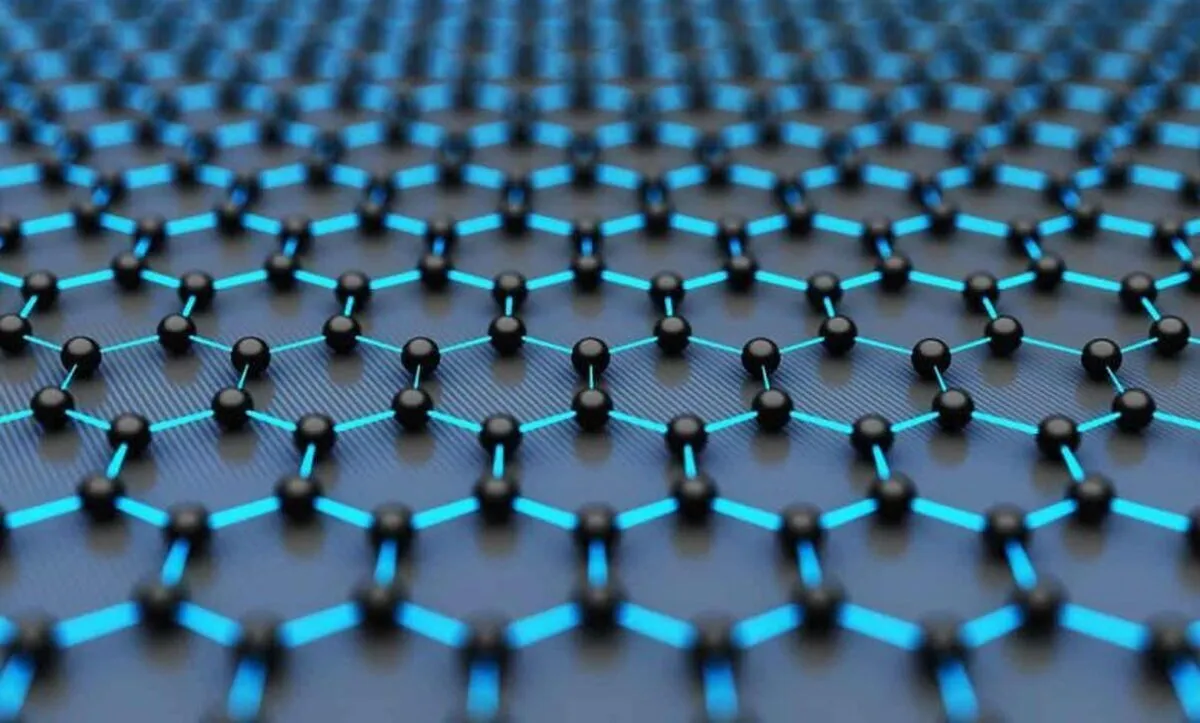

Iranian Knowledge-Based Firm Indigenizes Graphene Production Technology

“The company's initial products include graphene powder and graphene oxide. Aria Graphene Technology Company has been able to completely localize the graphene production technology,” Banayee, the commercial manager of Aria Graphene Technology company, told ANA on the sidelines of the 16th International Nanotechnology Exhibition in Tehran.

“Our subsequent products include anti-corrosion paint, flame retardant paint, and conductive ink. We also have collaborations with parent industries in the field of automobile tire production, optimization of bitumen production, and projects related to Isfahan Asphalt Company. We are also conducting research and development in the field of optimizing concrete production,” he added.

“We are also active in the field of strengthening, lightening, and creating internal and external drying textures of concrete. After about 15 years of scientific and practical research, graphene's target market has focused most of its attention on the fields of bitumen, asphalt, and tire manufacturing. The use of graphene in tire manufacturing reduces slippage and tire wear,” Banayee noted.

The 16th International Nano Technology Exhibition and the First Exhibition of Advanced Technologies of Iran was inaugurated at the Tehran International Fairground.

Held from November 2 to 5, the Nano Exhibition featured over 150 innovative companies showcasing advancements in nanotechnology. Meanwhile, the Exhibition of Advanced Technologies hosted 80 knowledge-based and technological products, attracting visitors, particularly students, researchers, and investors.

In a relevant development in October, Iranian researchers at Amirkabir University of Technology had also succeeded in increasing the lifespan and capacity of lead-acid batteries by developing a composite based on graphene aerogel.

“In this project, nitrogen-doped graphene aerogel along with zinc oxide nanoparticles was synthesized using a simple and cost-effective chemical reduction method,” said Arash Qazi Tabaar, a PhD graduate in Materials Engineering from Amirkabir University of Technology and Assistant Professor at the Color Research Institute.

“The structure of this material has meso-macro porosity with a high specific surface area, which maximizes electrolyte permeability. Laboratory samples of batteries produced with this technology have shown longer lifespan and higher capacity compared to conventional batteries,” he added.

The innovation focuses on the use of 3D and nitrogen-doped graphene materials, which improve the conductivity and stability of electrodes, thereby enhancing battery performance under harsh operating conditions. Initial tests showed that samples made with this technology have higher durability and efficiency than conventional batteries.

4155/v