Iranian Scientist, Colleagues Develop Zinc-Air Battery for Clean Energy Storage

The Melbourne-based Monash University research team introduced a new catalyst that promises to enhance next-gen batteries with greater power, extended lifespan, and reduced costs.

They revealed that the innovation outperforms standard commercial catalysts made from expensive metals like platinum and ruthenium.

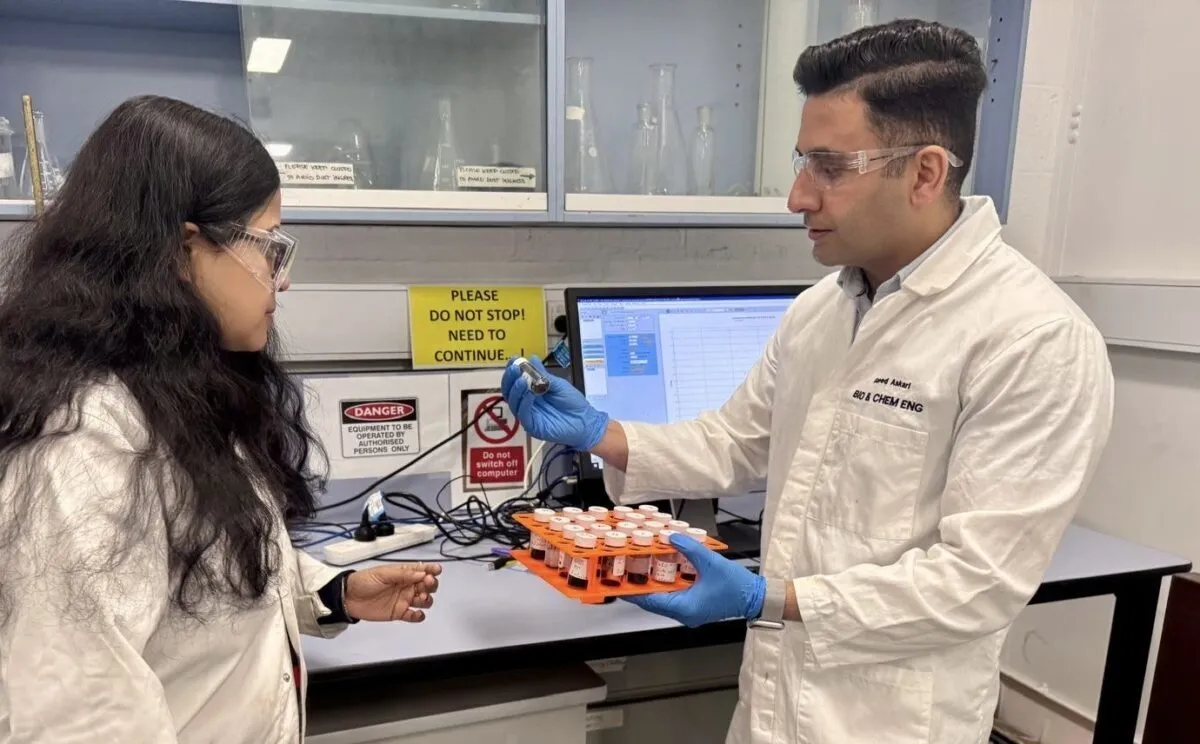

Askari, a PhD student at the university, along with Parama Banerjee, PhD, a senior lecturer in the department ofchemical and biological engineering, who led the research, reportedly used heat treatment to turn 3D material into ultra-thin carbon-sheets.

“By engineering cobalt and iron as individual atoms on a carbon framework, we achieved record-breaking performance in zinc-air batteries, showing what is possible when catalysts are designed with atomic precision,” Askari reported.

Zinc-air batteries (ZABs) are metal-air electrochemical cells powered by the oxidation of zinc with oxygen from the air. They comprise a zinc metal anode coupled to oxygen through an air anode.

Known for their high energy density, low cost, and environmental friendliness due to zinc’s abundance, zinc–air batteries are gaining increasing attention. They are emerging as a promising solution for high-capacity applications such as portable electronics, electric vehicles, and renewable energy storage.

ZABs are usually non-rechargeable, but researchers are working on making them rechargeable for use in electric vehicles (EVs) and large-scale energy storage.

Still, the practical application of these batteries mainly faces two challenges, such as limited output power and poor charge-discharge stability.

To address the challenge, the two engineers at Monash University broke all performance records in zinc-air batteries. The researchers reportedly utilized heat treatment to turn 3D material into carbon-sheets and added cobalt atoms to produce a faster and more efficient solution.

The experiment produced a battery that lasted 74 days and endured 3,570 charging cycles using cobalt and iron as the cathode materials.

“Our advanced simulations revealed that the cobalt-iron atom pairs, combined with nitrogen dopants, enhance charge transfer and optimize reaction kinetics, solving one of the biggest bottlenecks for rechargeable zinc-air batteries,” Askari explained.

The battery showed excellent performance. It delivered a power density of 229.6 milliwatts per square centimeter (mW/cm2) and an energy density of 997 watt-hours per kilogram (Wh/kg).

To examine the design, the two researchers carried out ongoing battery tests over the course of two months. “Running a rechargeable zinc-air battery continuously for more than two months is a milestone for the field,” Banerjee elaborated.

The results showed exceptional performance and stability in a rechargeable zinc-air system. Banerjee revealed that the principles behind the design can be applied to other clean energy technologies. Among these are fuel cells, water-splitting, and CO2 conversion.

Zinc-air batteries are currently used in small devices like hearing aids. However, the engineers believe the new development opens the door to rechargeable, high-power applications.

According to Banerjee, the innovation represents a turning point in the field. “It demonstrates that this technology is ready to move beyond the laboratory and into practical applications,” she concluded in a press release.

4155/v