Iranian Knowledge-Based Firm Acquires Technical Know-How of Making Industrial Stirred Reactors

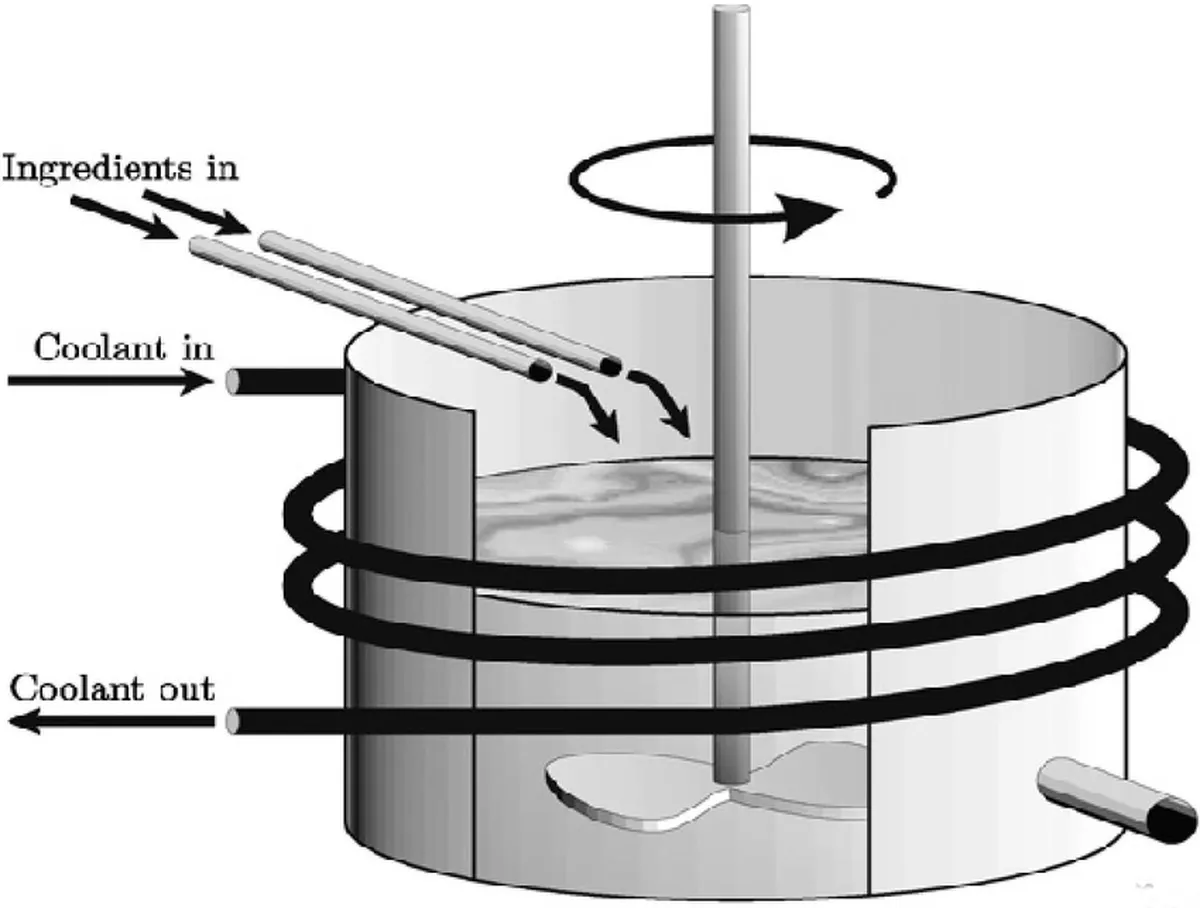

“These stirred reactors are used to mix materials with high viscosity (up to 8 million centipoise), including resin materials, adhesives, concrete and pastes that are sticky, and by using them, the mixing time of the materials can be minimized,” Mohammad Reza Fazeli, the managing director of the knowledge-based company.

“The way the impellers rotate and their small distance from the tank wall and each other will lead to the creation of a significant shear force for effective mixing, reducing the mixing time and also completely homogenizing the final product,” he added.

Noting that in conventional single-propeller mixers and in two-propeller mixers with fixed axes, it is not possible to mix high-viscosity materials, Fazeli explained that the materials stick to the container or impeller and escape from the mixing area, not mixing together in a dead space.

“This device is used to produce industrial adhesives, conductive adhesives and inks, battery paste, silicone paste, lightweight composites, medical pastes, dental compounds and materials, thick and viscous creams and lotions, medicinal gels, sealants like urethane, cement paste, magnetic slurries, soldering paste, lubricants and adhesives in the military industry,” he added.

In a relevant development in December, Iranian engineers at a technological company had succeeded in designing and manufacturing V-shaped blenders which can fully mix two materials in oil industry.

“The design and production of physics laboratory equipment is one of our main research fields. Besides that, we have also designed and manufactured laboratory equipment for the oil industry,” said Ramin Siami, one of the researchers of the company.

He referred to the latest achievement of this company, i.e. V-shaped blenders, and stated, “These devices are made in different capacities from 5 liters and 10 liters to 100 liters and more, and they have a special ability to mix powder materials that are difficult to combine with normal methods.”

“This device completes the mixing process with successive taps in two clockwise and counterclockwise directions. The desired materials enter the V-shaped cylinders of this blender and collide with each other with continuous blows and are completely mixed in a certain period of time,” Siami added.

“The special features of these mixers, like the V-shaped design and precise operation, have caused these devices to be used as one of the advanced laboratory equipment in various fields, including the oil industry and other related industries,” he said.

4155/v