Iranian Scientists at Amirkabir University Make Efforts to Facilitate Production of Microstructures

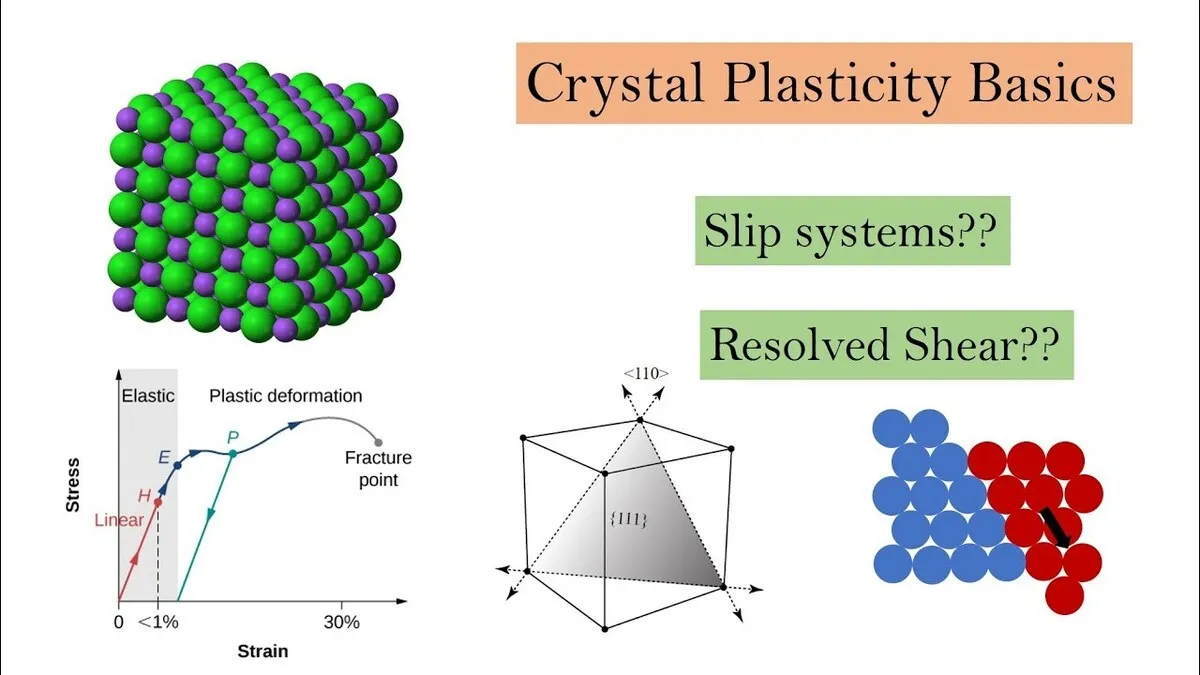

“Polycrystalline materials behave very differently at the scale of crystal grains than at the macro scale. In recent years, the use of crystal plasticity theory has attracted the attention of researchers since by modeling the governing physical laws at the meso scale, it is also possible to extract the material properties at the macro scale,” Morovvati said.

“Double-layer aluminum sheets are widely used in the industry due to their wide application. Double-layer sheets are used in medical equipment, ventilation equipment, precision electronic devices and in telecommunication industries,” he added.

Noting that the usual method of producing these sheets is the rolling process, Morovvati said, “Inhomogeneity among grains in the texture of crystalline metals causes incompatibility between grains. Polycrystalline materials on the micro and meso scale, i.e. the crystal grain size scale, show very different behavior from what they have on the macro scale.”

“Multi-scale modeling removes most parts of the need for laboratory operations to produce microstructures for researchers. Using this research, an accurate method can be obtained for the effects of deformation parameters during the rolling process of double-layer sheet which improves the double-layer sheet rolling process,” he added.

Polycrystalline materials are solids that consist of many small crystals (the grains).

The grains are separated by grain boundaries and normally have random crystallographic orientations. The size of the grains may vary from nanometers to millimeters.

4155/v