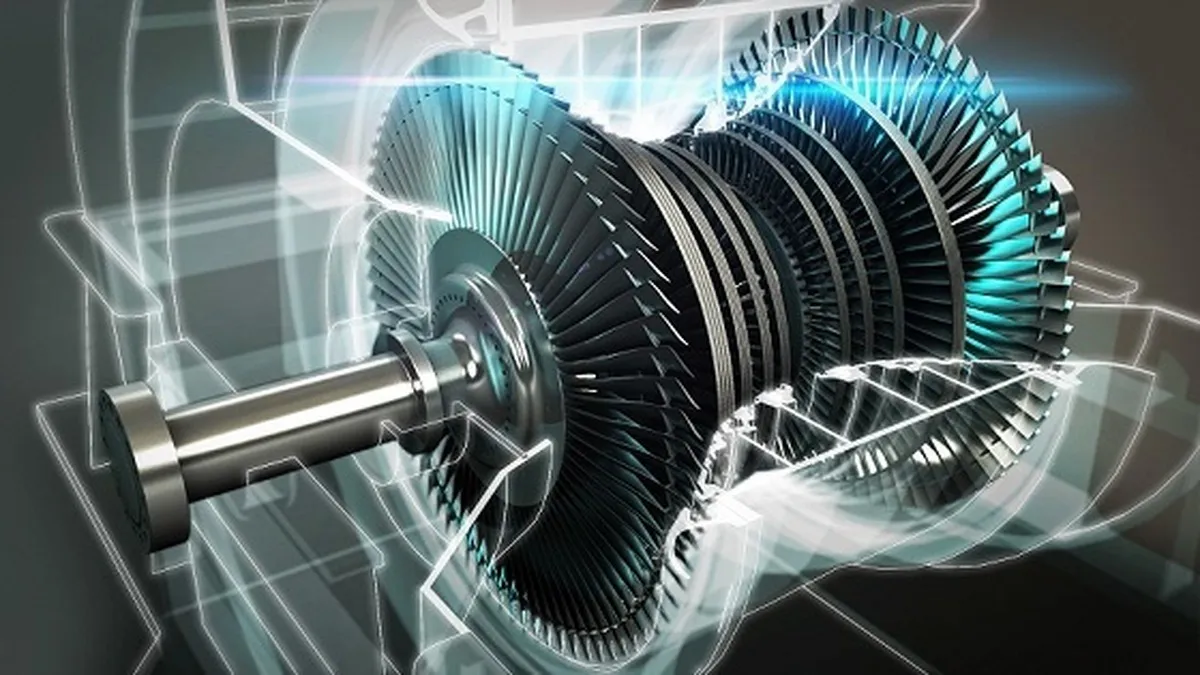

Iranian Researcher Settles Problem of Water Droplets on Blades of Steam Turbines

“The presence of liquid phase in the low-pressure stages of steam turbines can cause energy loss, problems related to wear and corrosion of the blade and reduce the efficiency of the steam cycle, which costs highly expensive due to the high price of steam turbines,” Seyed Ali Hosseini, a PhD graduate of Mechanical Engineering at Islamic Azad University’s Bushehr branch told ANA.

“In a bid to reduce the production liquid fraction in the steam turbine blade, the drain groove technique can be used,” he added.

Noting that the discharge groove was used in this research for the suction of super-cold steam and the liquid phase produced in the turbine blade, Hosseini said, “By optimizing the discharge groove, efforts were made to reduce the condensation loss, wear rate and entropy production in the steam turbine blade.”

“To achieve this goal, the multi-objective optimization-based TOPSIS method was used,” he added.

“The results show that the optimal mode is at location 3, the angle is 90 degrees, the inlet width is 0.06, and the suction pressure is 80 kPa. Therefore, condensation loss and abrasion rate decrease by 5% and 62%, respectively, and entropy production increases by 1.03%, and the liquid droplet removal percentage and suction percentage are 3.22% and 3.8%, respectively,” Hosseini said.

In a relevant development in August, an Iranian nanotechnology firm in Iran had also managed to produce refractory and high-temperature nanoparticle-containing ceramic for gas turbine combustion chambers.

‘Atlasceram Kavir’ company made the ceramic refractory matrix nanocomposite which successfully tolerates the elevated temperatures (from 1,100 to 1,850 K) and high pressures (from 5 to 10 atm).

It is highly corrosion-resistant, endures strong thermal shock, and benefits a long lifespan.

Adding hard nanoparticles to the ceramic matrix has resulted in increased mechanical strength, better dimensional accuracy, proper thermal shock resistance and longer lifetime at elevated temperatures and high pressures.

The refractory can be used in the internal walls of combustion chamber in gas turbines and it can also be utilized as crucibles and melt paths in ferrous and non-ferrous metals industries.

4155/v