Iranian Experts Use Nanotechnology to Manufacture Eco-Friendly Electric Coating for Walls

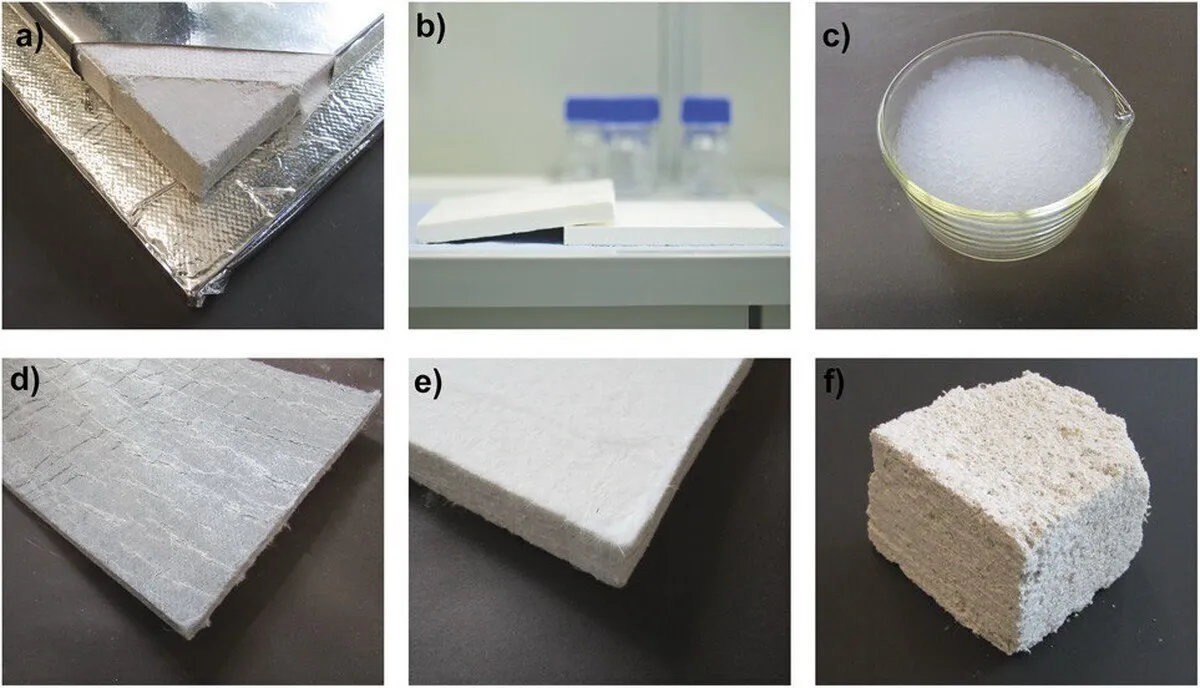

“This wall coating is made of conductive materials and thin heating elements that transfer heat directly to the walls when an electric current passes through. Unlike traditional systems that first heat the air, this technology directly heats surfaces and objects, preventing energy waste,” Davoud Beheshtizadeh, a PhD student in Civil Engineering with a focus on Construction Management at Islamic Azad University’s Tabriz branch, told ANA.

“Energy savings, carbon emissions reduction, uniform heat distribution, and the use of solar energy are the advantages of this product which reduces costs and dependence on fossil fuels,” he added.

“This coating generally consists of several thin layers, one of which is made of conductive material and is designed to produce infrared waves when connected to electricity. These waves increase the temperature by directly transferring heat to objects and people in the environment.

In a relevant development last year, researchers at a knowledge-based company in Iran had been able improve the durability of compressors in oil and gas industry by up to 300 times using ultra-hard coating equipment.

Hassan Jahdi, the managing director of the Iranian technological company, said that producing ultra-hard coating equipment using the PVD method is the main field of activity of their company. He pointed to the importance of using coatings in the industry, saying, "In some parts of compressors, the use of coating can increase the durability of the parts significantly."

“Nanocoating technology has become really popular in industry that it is known as a mother industry. The reason for this is the role that coatings play in an industrial product. In various industries, we are faced with parts that have different mechanical properties, durablity, wear and corrosion resistance, and we can apply special properties to the surface through coatings to increase the lifespan of the parts,” Jahdi said.

“In the oil and gas industry, we use nano-coating to reduce corrosion and bring it under control,” adding, “Oil extraction and exploitation take place in special conditions. This industry has a very corrosive working condition. But if coating is used, it can help reduce rate of corrosion.”

“In gas turbocompressors, coating is applied to control the wear and corrosion. It is considered a high-tech technology in the world. Increasing the efficiency and lifespan of these compressor parts, which are usually very expensive and important parts, is one of the applications of coating,” the engineer explained more.

4155/v