Iran-Made BLDC Electric Motor Saves Up to 50% of Energy

“We have succeeded in designing BLDC motors in three frame sizes from 250 W to 50 kW peak power,” said Rahimi, the managing director of the knowledge-based company.

“The motors made by our company which are used in water-cooled air conditioners and industrial fans bring about 40% to 50% electricity savings,” he added.

“Due to their continuous rotation, these motors can compensate for the pressure drop and practically there is no need to electricity produced in two or three power plants in the country,” Rahimi said.

“By installing these engines, this year water-cooled air conditioners will be produced with grade A and A Plus in the country which will significantly reduce energy consumption,” he noted.

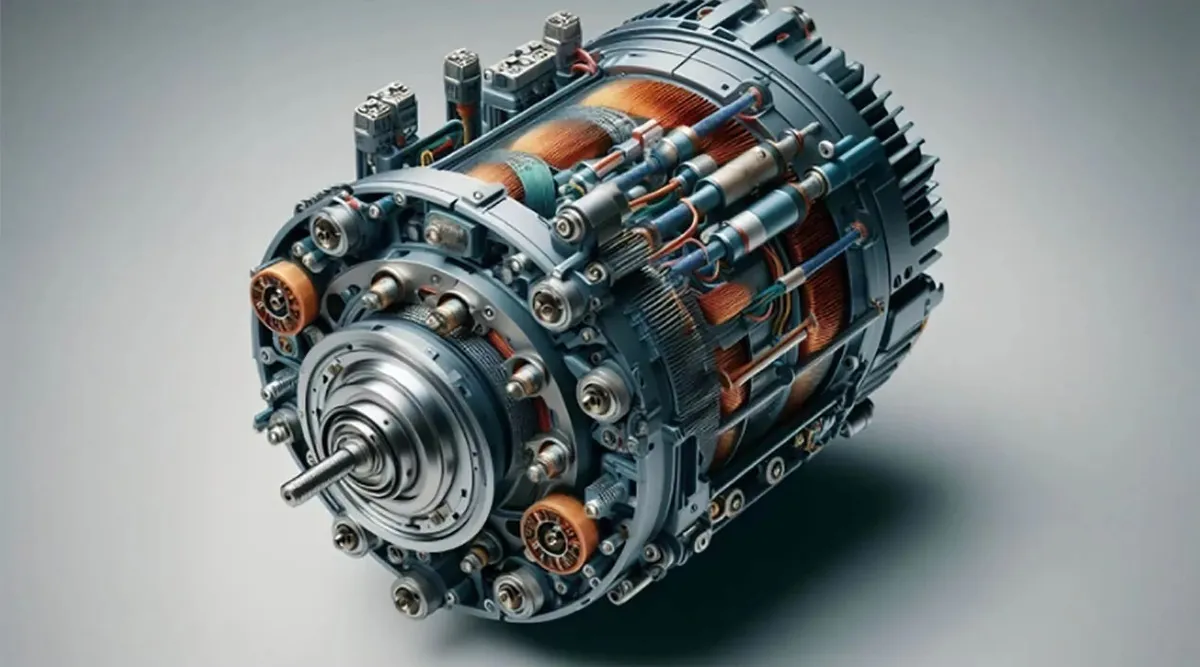

A brushless DC electric motor (BLDC), also known as an electronically commutated motor, is a synchronous motor using a direct current (DC) electric power supply. It uses an electronic controller to switch DC currents to the motor windings producing magnetic fields that effectively rotate in space and which the permanent magnet rotor follows. The controller adjusts the phase and amplitude of the current pulses that control the speed and torque of the motor. It is an improvement on the mechanical commutator (brushes) used in many conventional electric motors.

The construction of a brushless motor system is typically similar to a permanent magnet synchronous motor (PMSM), but can also be a switched reluctance motor, or an induction (asynchronous) motor. They may also use neodymium magnets and be outrunners (the stator is surrounded by the rotor), inrunners (the rotor is surrounded by the stator), or axial (the rotor and stator are flat and parallel).

4155/v