Iranian Company Makes 3D Printers for Producing Gold, Jewelry

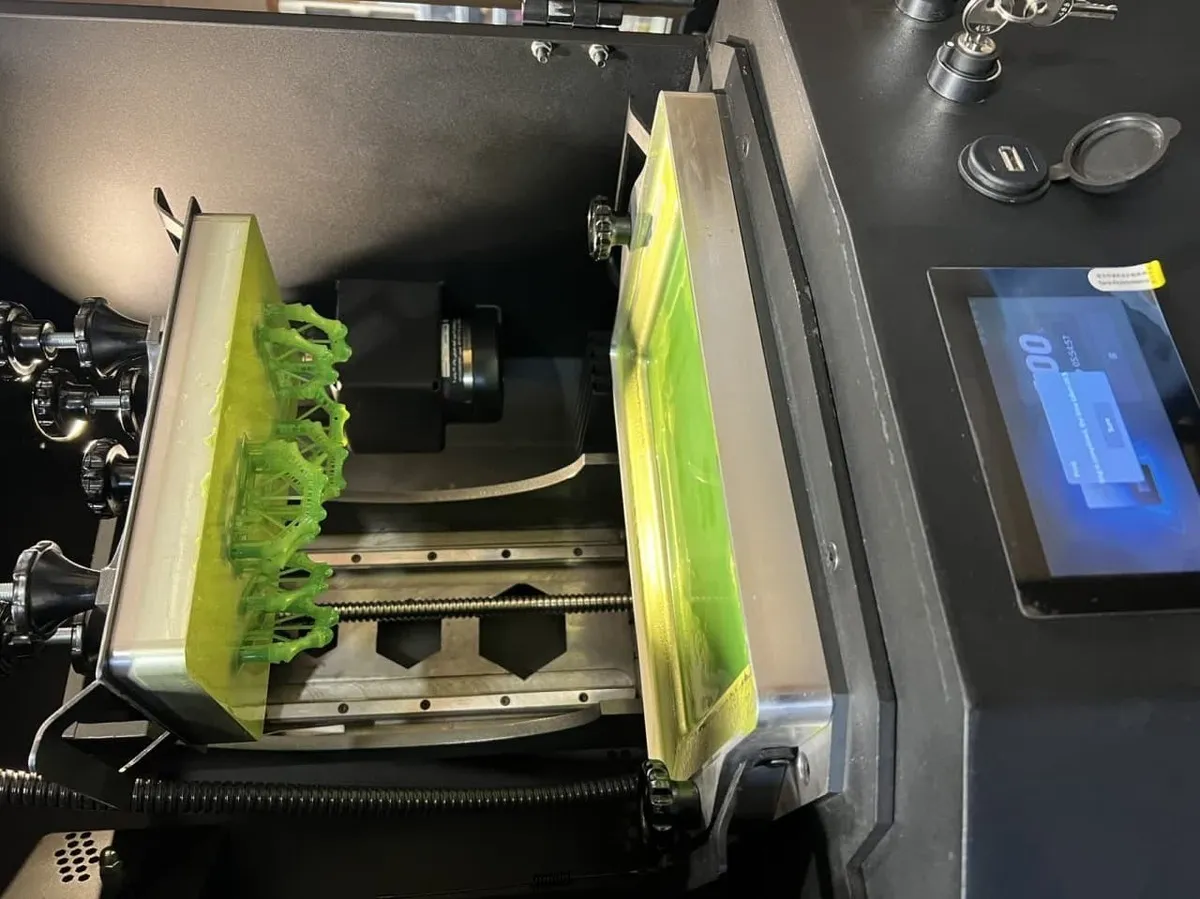

The technological company, stationed at the incubator center of Islamic Azad University’s Tabriz branch, has manufactured 3D printers in the fields of goldsmithing, dentistry and modeling, a report said.

“Among the achievements of our company, we can mention the indigenization of certain 3D printing technologies with specific technical specifications and presentation of innovations that have promoted this industry and are now being emulated by other industrial activists,” Shahriar Nezakat, the managing director of ‘Kohan Sanatgaran Khallag’ company, told ANA.

“The development and production of 3D printing machines, related machines, peripheral equipment and consumables are among our activities. Also, among the products currently being produced by our company, we can mention 3D printers with DLP and LCD technology, ultra-precise casting resins, and post processing devices,” he added.

Noting that his company has successfully completed the research and development stages of the 3D printer with SLM technology, Nezakat said, “We hope to produce the prototype of this product, whose technology is in the hands of a few countries like the US and Germany, soon.”

In a relevant development in April, specialists of an Iranian knowledge-based company had also succeeded in direct production of the most complex industrial parts with the highest accuracy by producing metal 3D printers equipped with Selective Laser Melting (SLM) technology.

“SLM technology, which uses alloy powder as a raw material and laser as a manufacturing tool, enables the production of parts with any complexity directly from their 3D file. In this method, the final metal product with any complexity is made directly from its 3D file without the need to any special secondary operations,” said Ahmad Forouzmehr, the managing director of the knowledge-based company.

“In this process, high power laser is used to melt metal powder and mix them together. When a layer is formed, a new layer of powder is spread over the surface. The thickness of the layers varies from at least 20 to 100 microns,” he explained.

Forouzmehr said that among the materials used in the process are tool steel, stainless steel, cobalt chrome and titanium, adding when reactive materials like titanium or aluminum are used, the amount of oxygen in the sealed chamber should be minimized to prevent oxidation of the material and subsequent defects.

“To reduce oxygen, it is sufficient to fill up the chamber with pure argon gas. This machine is used to make parts required for power plant, aerospace, automotive, industrial, medical and dental molds. This device also enjoys many capabilities in the field of research in areas of mechanical engineering and metallurgy,” he noted.

4155/v