Iranian Knowledge-Based Company’s Experts Improve Accurate Assessment of Data with New Calibration Device

“Measurement directly affects the quality of the product or the sample that is measured and controlled because the first step to guarantee the quality of a prototype product that is controlled by the measurement method is to guarantee the quality of the measurement result which will be materialized by calibration of the measuring equipment,” said Somayyeh Ebrahimi, a member of the board of directors of the knowledge-based company.

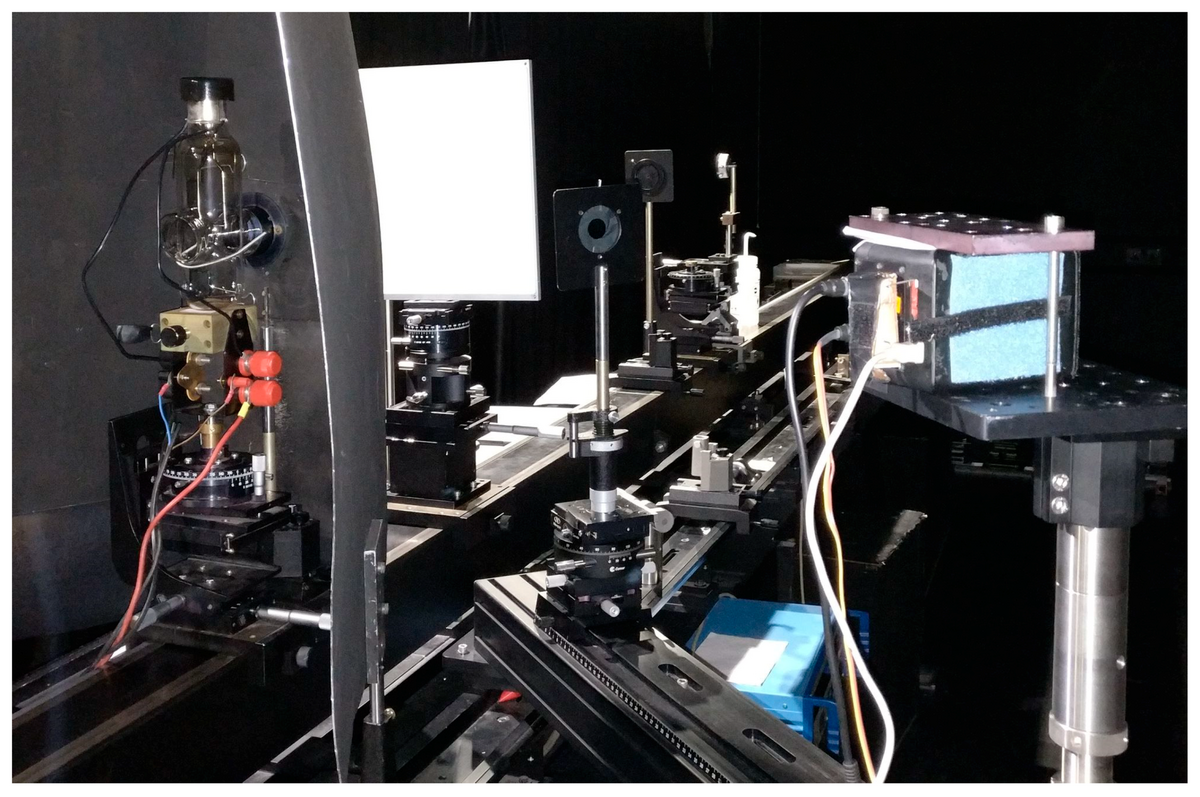

She explained that if the data obtained from the measuring devices in various stages of inspection and testing are not accurate and correct, the basis of the analysis in the industrial centers is not correct and certainly misleads these centers and even causes irreparable damages in many cases, noting, “Therefore, we have provided the calibration device to improve the accuracy of the measuring devices so that the errors are eliminated.”

Ebrahimi described creation of the public trust at the community level in business, service and health processes and a legal framework and culture to protect rights and prevent losses in commercial exchanges with other countries as some of the most important advantages of calibration.

System calibration is designed to quantify and compensate for the total measurement error in industrial control systems.

An error model could be as simple as a lookup table of input versus output values, or as detailed as a polynomial. Once developed, it can be applied to all measurements made with the same system.

4155/v