Iran Exports Digital, Solar Spinning Machine to Neighboring States

“In the process of producing yarn from wool, processing should be done on the wool first. The wools used to produce yarn are from goats, camels or sheep, which should be combed before using,” said Mehran Zeiqami, the managing director of the company.

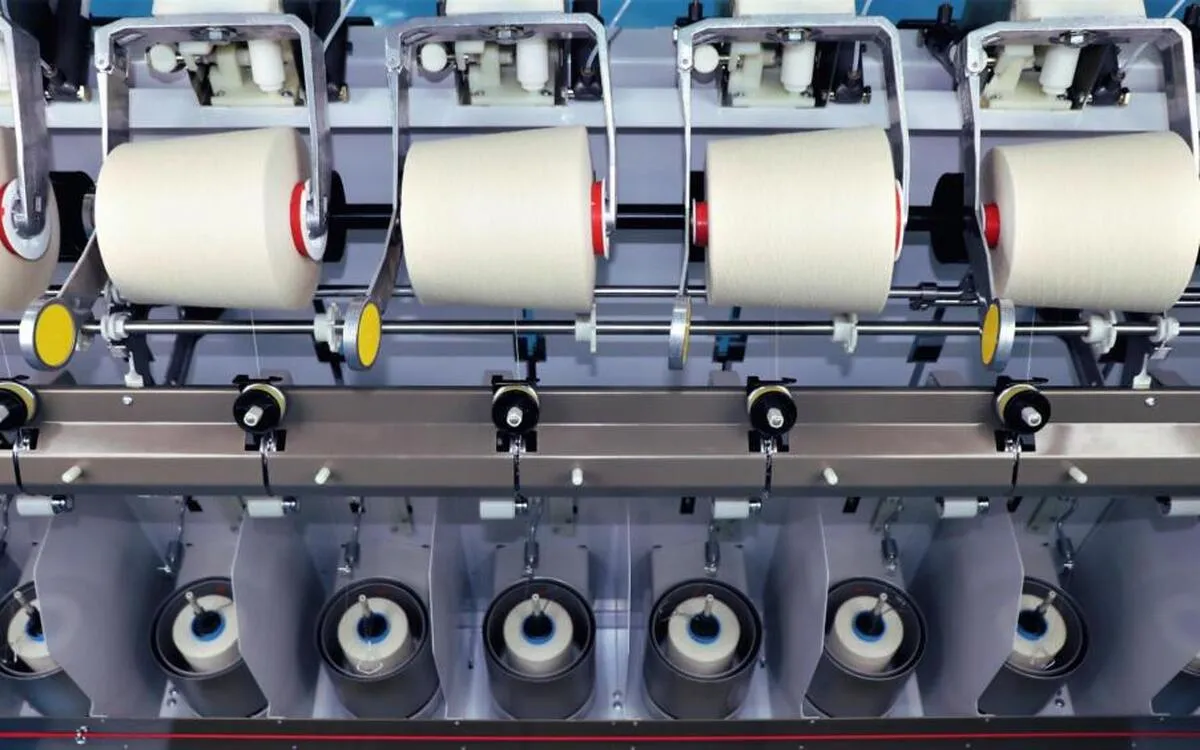

“For this purpose, we produced the new spinning machine, which allows the user to convert sorted wool into spinnable wool. The price of the device is one-twentieth of the price of the foreign sample, and its weight and sound are less than similar samples in the market,” he added.

Noting that the spinning speed of this machine is 10 times higher than traditional methods, Zeiqami said that the device consumes between 60 and 70 watts.

“We have produced various samples of this device so far, and in addition to producing the digital version, we also succeeded in making a solar sample of this device,” he added.

“Our spinning machine also has many fans in Afghanistan, while the countries of Tajikistan, Indian Kashmir, Kyrgyzstan and Iraq are other customers of these machines,” Zeiqami said.

In a relevant development in July, an Iranian student at the Islamic Azad University’s Neyriz branch has designed and produced an industrial spinning machine capable of being transported easily for nomads, villagers and yarn and carpet factories.

Milad Rokhshan, a mechatronics student at the Islamic Azad University (IAU)’s Neyriz branch, Fars Province, successfully designed, built and began mass production of an industrial spinning machine with the capability of easily being transported, especially for nomads, villagers and all those who are operating in the yarn and carpet production field.

The IAU student told ANA reporter that his machine comes with features such as being light, easy to carry and being cost-effective. “This machine can convert sheep's wool and that of goat and camel to thread.”

“Nomads and villagers usually do this work with a spindle by hand in traditional way. It takes them eight hours to make half a kilo of thread, while by using this machine they can produce about three kilos of thread with the same quality at that eight-hour period of time, indicating that six times more than the amount produced in the traditional and manual way.”

4155/v