Iranian Knowledge-Based Company Manufactures Electronic Parts for Domestic Auto Industry

“Our company produces a wide range of electronic components for the automobile industry. Our factory has different departments, each of which is doing a specific job. This guarantees the production of the highest quality products,” said Mohammad Hassan Asteraki, the technical manager of the knowledge-based firm.

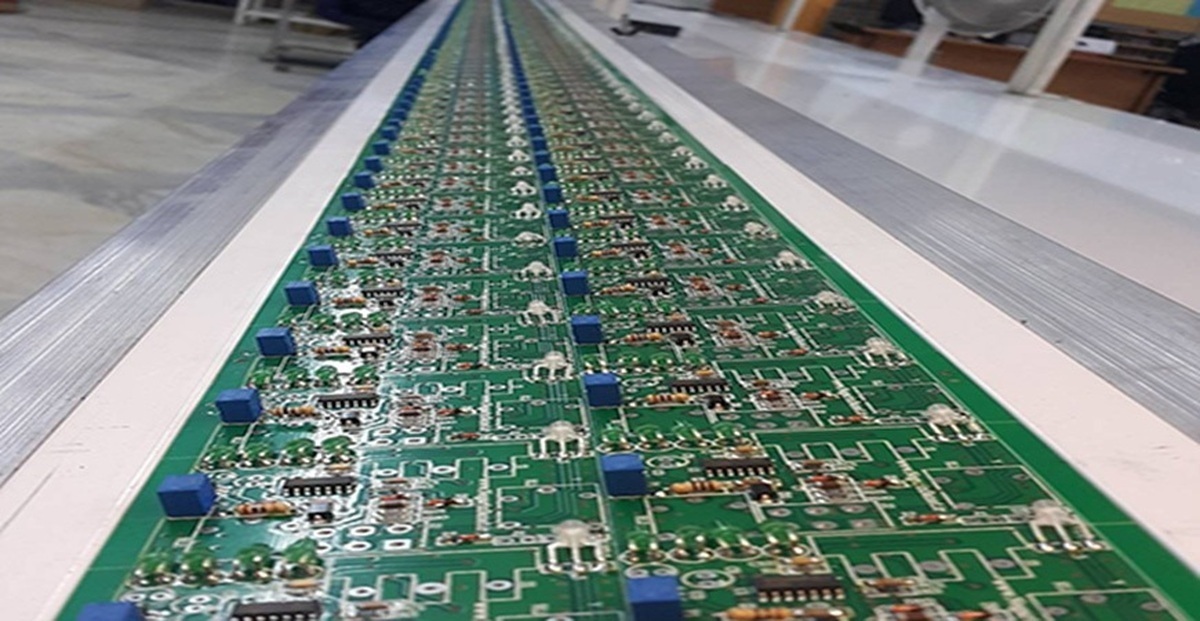

Saying that the different department in their factory consists of assembly of SMD boards; manual assembly and quality control departments, he added, “In the assembly of SMD boards, the most advanced equipment is used to automatically solder small electronic parts such as capacitors, resistors and switches on printed circuit boards. High accuracy and speed in this sector guarantee the production of high quality products that meet updated standards.”

“The assembly of some parts is done manually by experienced and trained personnel due to their delicacy or high complexity. This ensures precision and delicacy in the assembly of these sensitive parts. Also, in the quality control department, all manufactured products are fully tested and reviewed to ensure their correct performance and compliance with quality standards.”

“The products of this knowledge-based company include steering wheel keys for the domestically made vehicles Dena, Tara, Pars and Samand. In the production process of these parts, first the wires are bought in bulk from factories and then cut carefully. After that, the wires are pressed according to the specified sizes and are placed in the connector,” he explained more.

The technical manager of the company said that they have focused their work on domestically production of electronic components of cars, adding, “With the efforts of this company, many products that were previously imported from China are now produced inside the country; however, some parts such as switches and LEDs are still imported from overseas but the assembly, testing and finalization of the product is done inside the country.”

“We compete with the Chinese in this field, but due to the lower price of our products, we have succeeded in dominating the market,” Astaraki said.

“This knowledge-based company operates from production to consumption and is present in the supply chain of an automobile manufacturer, meaning that the production boards of this company are transported to another company, where plastic injection is done to their frames. Then these boards are sent to the other company that works in the field of steering wheel production, and finally the complete steering wheel is transferred to the car manufacturer's production line and installed in the vehicles,” he continued.

“This knowledge-based company has hired nearly 30 people and its research and development unit is also operating. People working in this company enjoy university degrees in various fields of engineering, including mechanical engineering, electrical engineering, physics and optics,” its technical manager further said.

As regards the challenges they have faced in producing the headlight and rain sensors, Astaraki said, “This product faces challenges in the fields of optics, mechanics and electronics, because these fields are closely connected to each other. Now we are in the process of signing a contract with a car manufacturer for the mass production of this product.”

With regard to the number of products produced by the knowledge-based company, the technical manager said, “This company has so far produced 12 products, six of which are currently in the mass production phase.”

4155/i