Iranian Knowledge-Based Company Manufactures Glucose, Hemoglobin Sensors

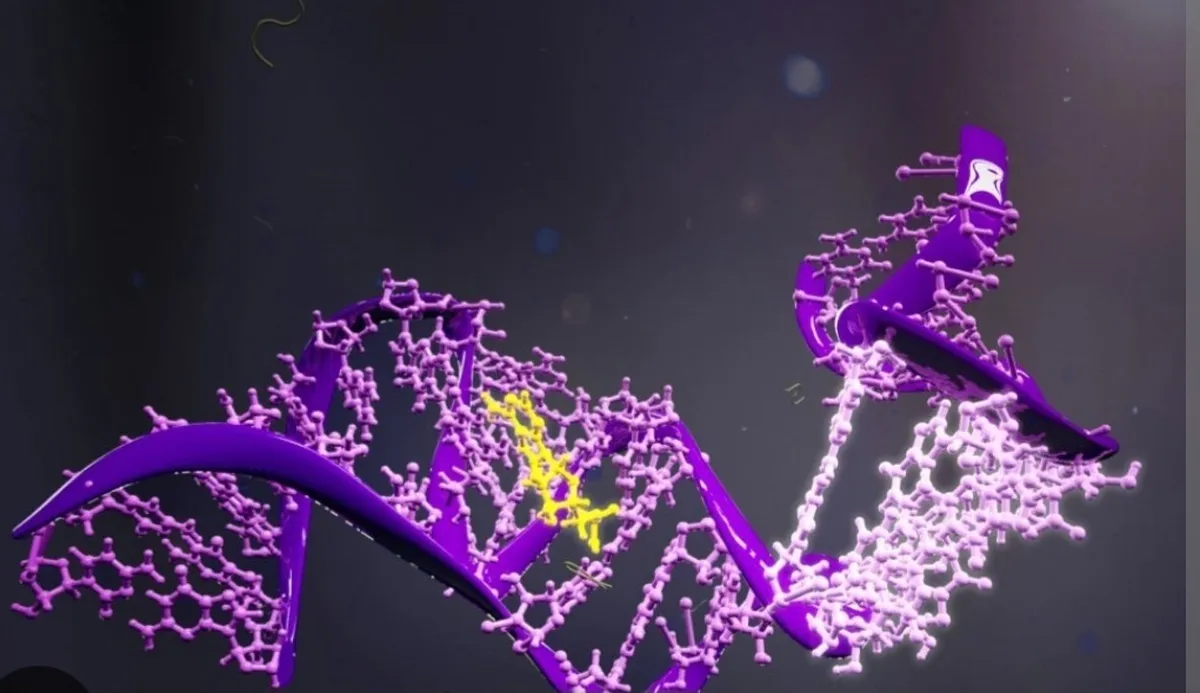

The researchers at a knowledge-based company based in the South Khorasan Science and Technology Park have launched production of aptamer-based biosensors. Using electrochemical methods, these sensors benefit from advantages such as high sensitivity, low detection limit, large linear detection range, and the possibility of being used in a broad range of solvents, electrolytes, and temperatures.

Using the microfluidics method based on the electric field, the company makes it possible to detect the aptamer sequence in only one round of the SELEX process. The selection process is done in the shortest possible time and at the lowest cost.

“The detection process in aptamer sensors is carried out on electrodes based on nanomaterials,” Rana Bagheri, the managing director of the knowledge-based company, said in an interview with ANA.

“Through research and development programs, the researchers of this company have succeeded in making electrodes based on LIG graphene, which due to its three-dimensional structure with high porosity increases the surface to volume and creates a more effective function for connecting to the target and increases the speed of heterogeneous electron transfer,” she said.

“Graphene powder, LIG electrode and silver ink are also other side products of this company. Graphene is a carbon material with unique properties. Among its interesting physico-chemical properties, it can be said that it has a very high specific surface area (2,630 g/m2 in single-layer graphene), excellent thermal and electrical conductivity, and high mechanical strength,” the researcher also said.

“LIG electrode is laser-induced graphene, which is obtained by irradiating polymers such as polyamide with a carbon dioxide laser and acts as a superconductor. Silver nanoparticles are also considered as the most suitable conductive ink due to their low resistance and high stability, which are used in printing and production of flexible electronic components,” Bagheri continued.

“We have used LIG laser-induced graphene biosensors, a technology that is only available in Scotland. These electrodes are similar to the electrodes of carbon screen printers, with the difference that they do not need to design a mask and make ink. Instead the process of making it is done in about a minute, and there is no need to repeat the process,” she said.

“When the electrodes are produced in a stable manner, they are ready to be used in making sensors. We have made the hemoglobin sensor at the request of Iran Blood Transfusion Organization. Our other manufactured sensor is the glucose sensor. This sensor is one of the fourth generation sensors that is made without using enzymes but with using nano materials,” Bagheri went on to conclude.

4155/i