Iranian Researcher Creates Plant-Based Microrobots for Medical Use

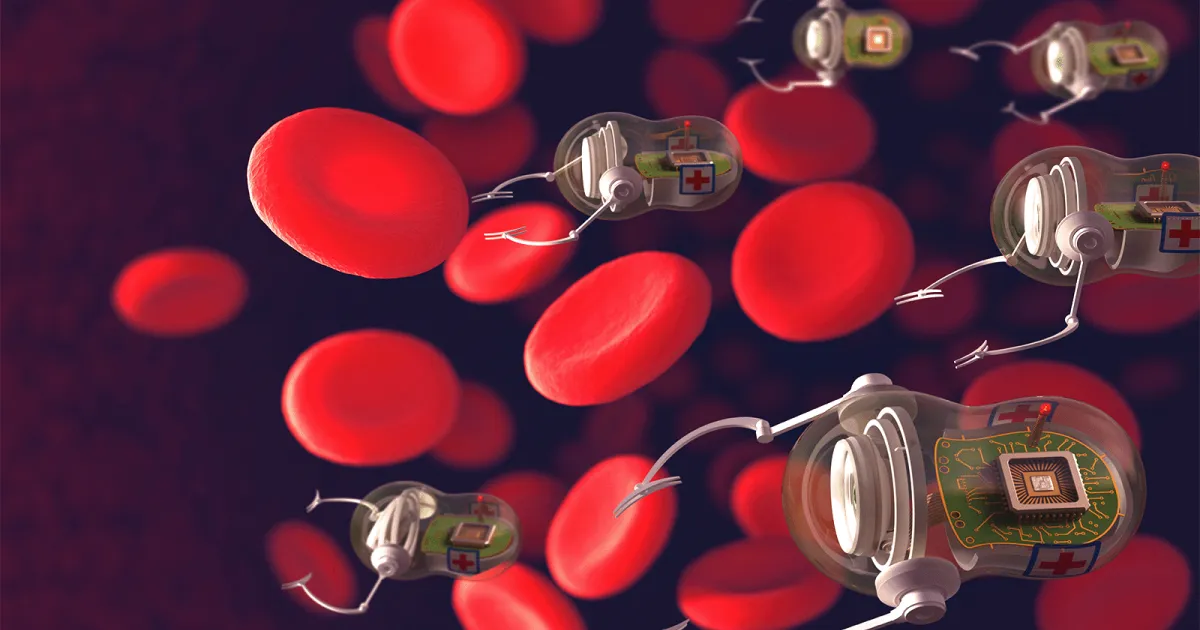

Led by Hamed Shahsavan, an Iranian chemical engineering professor, the research team has developed tiny robots that have the potential to conduct medical procedures, such as biopsy, and cell and tissue transport, in a minimally invasive fashion.

The tiny soft robots are a maximum of one centimetre long and are bio-compatible and non-toxic. The robots are made of advanced hydrogel composites that include sustainable cellulose nanoparticles derived from plants.

The hydrogel used in this work changes its shape when exposed to external chemical stimulation. The ability to orient cellulose nanoparticles at will enables researchers to program such shape-change, which is crucial for the fabrication of functional soft robots.

"In my research group, we are bridging the old and new," said Shahsavan, director of the Smart Materials for Advanced Robotic Technologies (SMART-Lab). "We introduce emerging microrobots by leveraging traditional soft matter like hydrogels, liquid crystals, and colloids," he added.

The other unique component of this advanced smart material is that it is self-healing, which allows for programming a wide range in the shape of the robots. Researchers can cut the material and paste it back together without using glue or other adhesives to form different shapes for different procedures.

The next step in this research is to scale the robot down to submillimeter scales.

In a relevant development in December, a group of scientists from different parts of the world had also cooperated in developing a mass-production method for biodegradable microrobots that can dissolve into the body after delivering cells and medications.

In order to create a technology that can produce more than 100 microrobots per minute that can be disintegrated in the body, Professor Hongsoo Choi’s team at the Department of Robotics and Mechatronics Engineering at the Daegu Gyeongbuk Institute of Science & Technology (DGIST) worked with Professor Sung-Won Kim’s team at Seoul St. Mary’s Hospital, Catholic University of Korea, and Professor Bradley J. Nelson’s team at ETH Zurich.

There are many approaches to building microrobots with the goal of minimally invasive targeted precision treatment. The most popular of them is the ultra-fine 3D printing process known as the two-photon polymerization method, which triggers polymerization in synthetic resin by intersecting two lasers.

This technique has the ability to create structures with nanometer-level accuracy. The drawback is that it takes a lot of time to create a single microrobot since voxels, the pixels realized by 3D printing, must be successively cured. In addition, during the two-photon polymerization process, the magnetic nanoparticles in the robot may block the light path. When utilizing highly concentrated magnetic nanoparticles, the process result may not be uniform.

4155/v