Iranian Nanotechnology Firm’s Thermal Insulation Used in Industries, Buildings

“This product is a thermal insulation coating that replaces traditional products. The use of nanomaterials improves the performance of the thermal insulation so that the heat transfer coefficient decreases in this product and the specific heat of the coating increases,” said Narges Saffarian, the chairwoman of the board of directors of ‘Pousheshhay-e Mohafez Payeh Aab Pavan’ group.

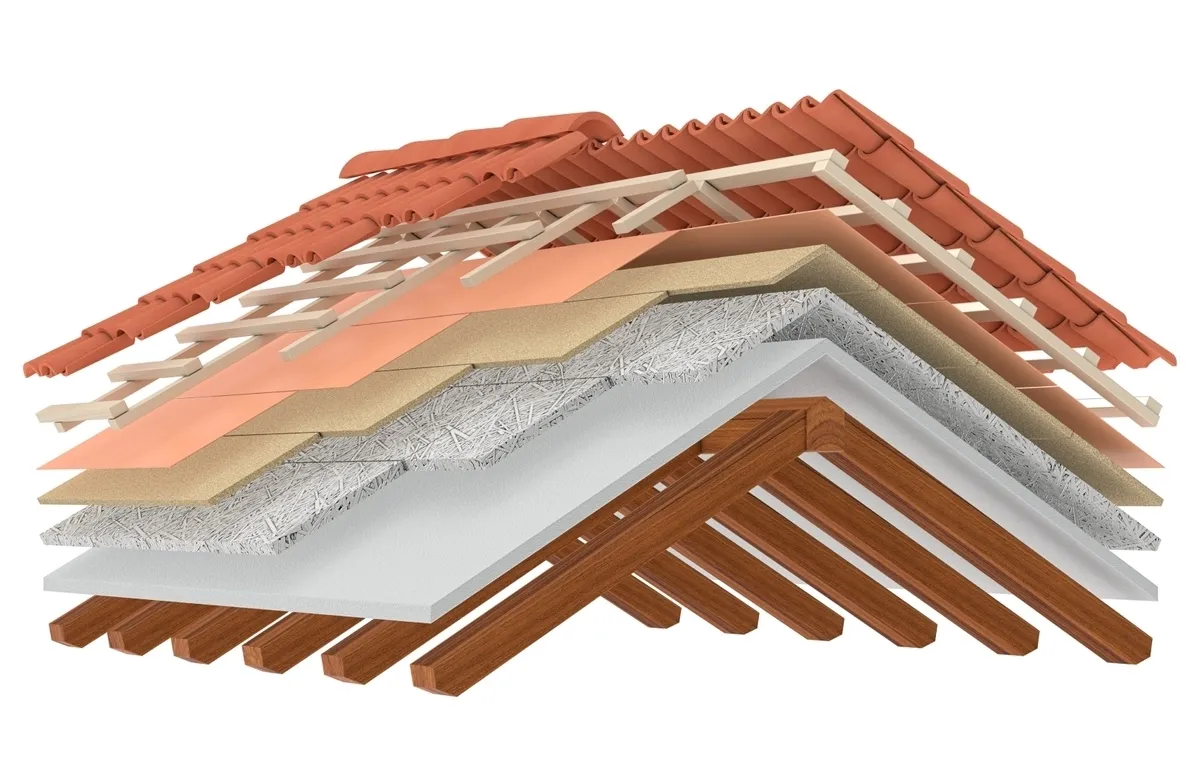

“This coating is used in much smaller thicknesses than glass wool and stone wool which is of great importance in building facilities. The durability of this insulation is high and it does not have the corrosion common in industrial coatings. The insulation itself adheres to the surface and is highly durable due to the elimination of condensation,” she added.

“The product is proper for reducing the temperature of the external surfaces of industrial equipment, including tanks and reactors, and it also reduces fuel and energy consumption in equipment with high temperature and thermal energy, specially in petrochemicals, refineries and metal industries,” Saffarian said.

She noted that if the nano-based insulation is used in buildings, heat absorption will reduce and cold transmission through roofs, walls and attics will be prevented.

Earlier this year, another Iranian company had also developed a thermal insulator based on nanotechnology that is able to optimize energy efficiency in buildings.

The product can prevent the transfer of heat by thermal radiation, has high flexibility, and does not produce smoke or chemical pollutants.

Therefore, it is a suitable alternative to the existing traditional insulators.

The use of nanomaterials has improved the performance of the thermal insulator so that the heat transfer coefficient has decreased and the specific heat of the coating has increased.

4155/v