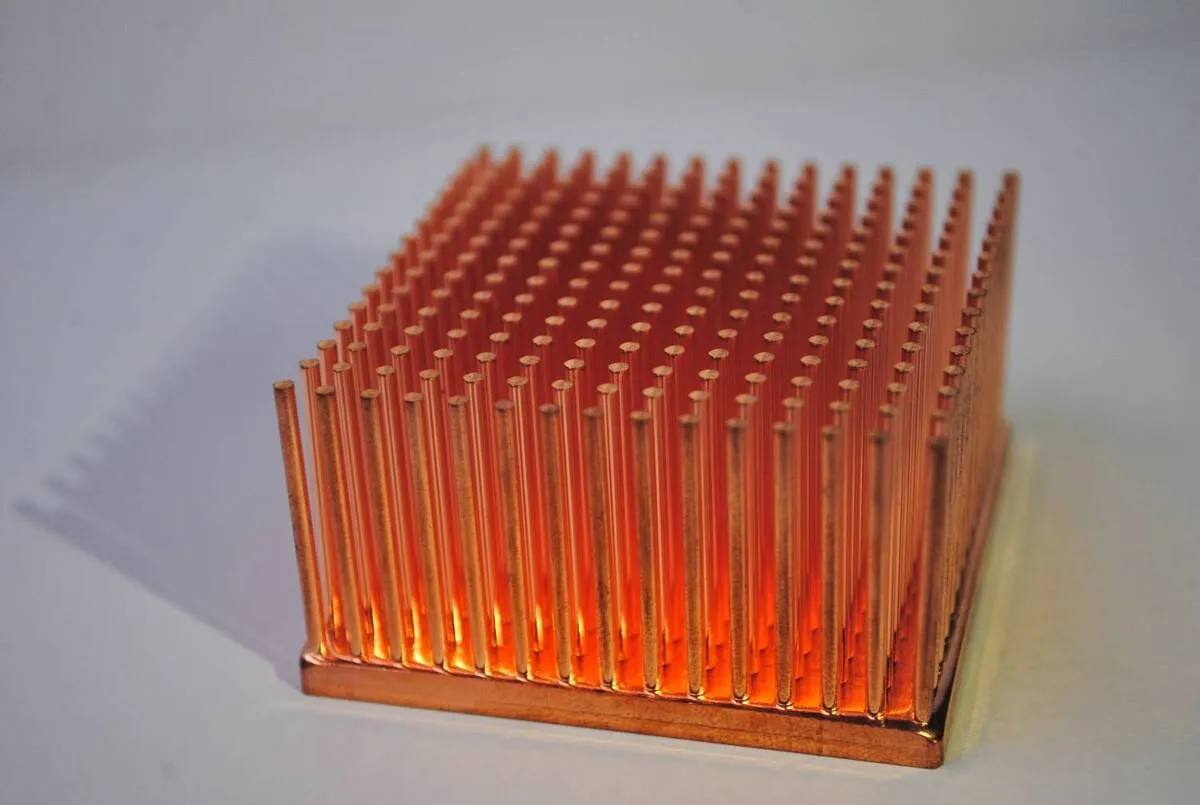

Nanoporous Alumina Used by Iranian Company to Make Heat Sink

‘Nano Abkar Isatis’ company made the heat sink whose surfaces are covered by thin layer of nanoporous alumina through anodizing which leads to better corrosion resistance and heat transfer kinetics.

Anodizing exterior surfaces of the heat sink and forming a thin layer of nanoporous alumina increases corrosion resistance, leads to better heat transfer owing to high surface area-to-volume ratio and improves thermal emission coefficient.

The heat sink can be used in production of microprocessors, light-emitting diode lamps and solders.

A heat sink is a passive heat exchanger that transfers the heat generated by an electronic or a mechanical device to a fluid medium, often air or a liquid coolant, where it is dissipated away from the device, thereby allowing regulation of the device's temperature. In computers, heat sinks are used to cool CPUs, GPUs, and some chipsets and RAM modules.

Heat sinks are used with high-power semiconductor devices such as power transistors and optoelectronics such as lasers and light-emitting diodes (LEDs), where the heat dissipation ability of the component itself is insufficient to moderate its temperature.

4155/v