Iranian Scientists Make Scaffold for Fibrous Tissues of Intervertebral Disc

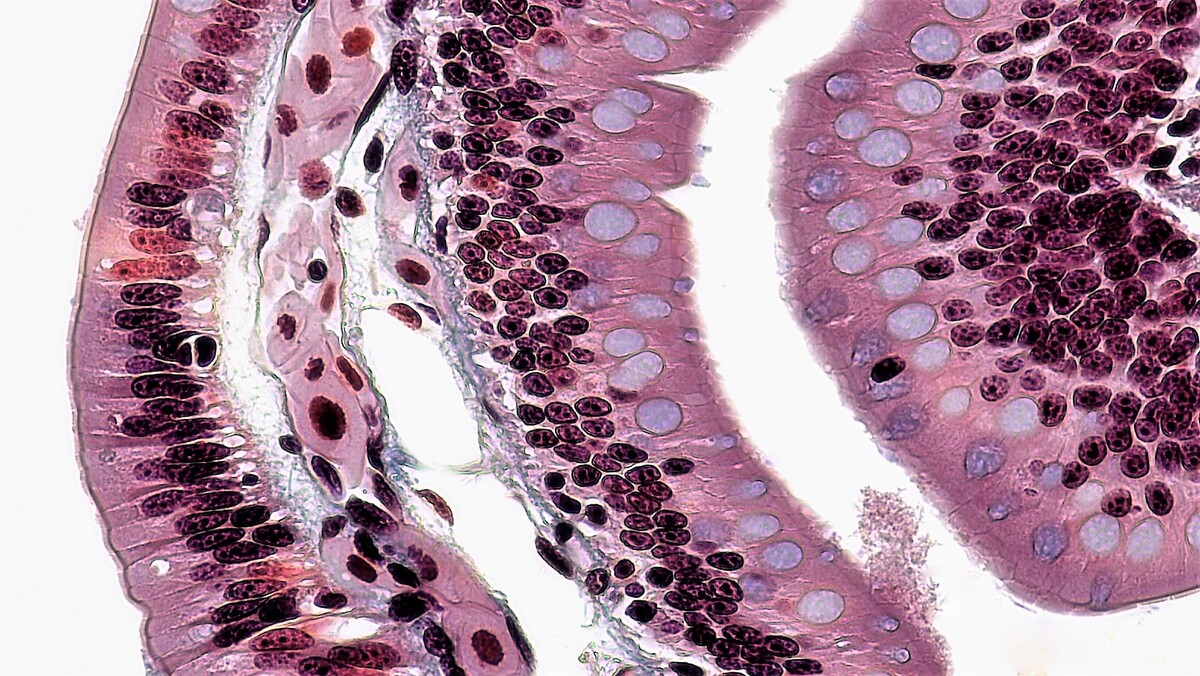

“Since the electrospinning method can produce engineered tissues with significant regeneration and multilayer structure with regular fibers and suitable mechanical properties, we decided to use this method to make the desired scaffold,” said Elham Rahim Toroqi, a PhD graduate of Amirkabir University of Technology in Tehran.

She noted that gelatin scaffold reinforced with electrospun PLLA yarn was finally prepared and its properties were investigated.

“The results of this research showed that adding electrospun nanofibrous yarns to pure hydrogel reduces porosity and swelling while increasing tensile strength and elastic modulus,” Rahim Toroqi said.

“Cell experiments also showed that cells had better adhesion, proliferation and expression on the surface of hydrogel reinforced with threads than pure hydrogel; therefore, due to the improvement of mechanical and cellular properties, thread-reinforced hydrogel compared to pure hydrogel can be used as a new scaffold for intervertebral disc fibrous tissue,” the researcher added.

She underlined that the mechanical properties of the scaffolding will be investigated in more details and in conditions close to the real conditions of the human body in the future, adding, “Also, animal tests will be performed on this scaffold.”

Rahim Toroqi explained that the new scaffold is a polymer scaffold made from a combination of natural gelatin polymer and PLLA synthetic polymer.

Also, late last year, an Iranian metallurgy scientist had proposed for the first time a project for industrial production of magnesium biodegradable scaffold by casting method for bone applications, a plan which leads to improvement of the healing rate of bone injuries.

“Using scaffolds as a suitable ground for the proliferation and growth of cells and tissues can help continued cell growth until the complete replacement of the spot by the host tissue,” said Abouzar Rezayee Barvati, a Ph.D. student in metallurgical and materials engineering at Islamic Azad University’s Najafabad branch.

Noting that various methods exist for making three-dimensional metal scaffolds for use in bone tissue engineering, he said, “One of the suitable methods for producing metal scaffolds is the casting method, which was used in this research. In this method, molten magnesium is cast in a special mold containing space-creating materials, and a magnesium scaffold is finally produced after removing the space-creating materials.”

“This method is very suitable in terms of uniformity of physical and mechanical properties and the cost of scaffolding, and it can be mass-produced and industrialized,” Rezayee Barvati said.

4155/v