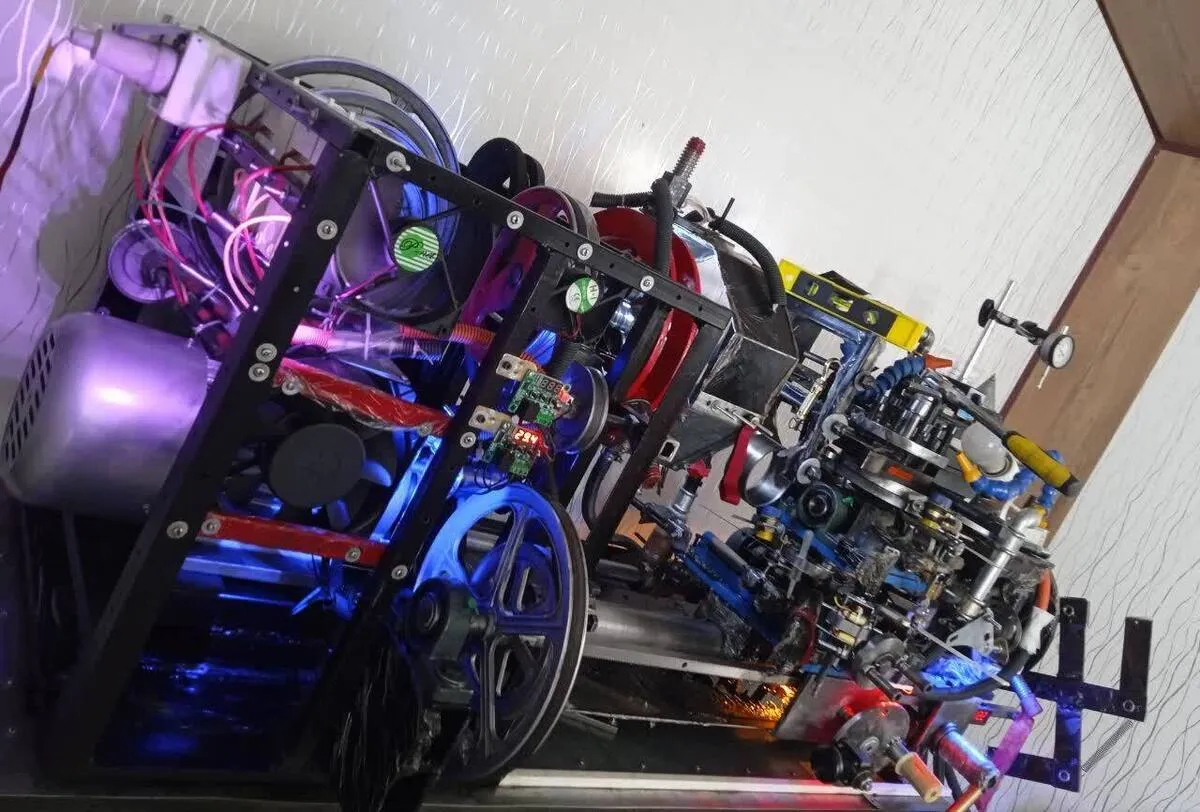

Knowledge-Based Firm in Iran Manufactures Practical Turning Machine with Application in Steel Industry

“This machine is suitable for turning all types of metals, and plastic and Teflon materials, and it enjoys the ability to cut via using an automatic mechanical cutting system,” Mostafa Tourchi, the manager of the knowledge-based company, told ANA.

“Among other capabilities of the machine mention can be made of possibility to unload four millimeters in one pass for roughing steel parts,” he added.

Noting that the machine is also suitable for training purposes, Tourchi said, “It is similar to the conventional turning machines in the market with the difference that several parameters have been improved in this product which has led to more integration in using the machine.”

He stated that in addition to the usual capabilities of manual lathes, the device has special features like off-center drilling capability and metal cutting by using automatic scissor-saw system.

Tourchi said that the main advantage of the device made by his company compared to similar and foreign samples is more operational and machining possibilities and lower production costs.

Earlier this year, Iranian researchers at Sharif University of Technology had also managed to find a new method to increase the productivity of mining and steel factories by presenting a technological idea titled ‘designing a non-stop automatic bullet feeding system to rotating shafts’.

“This machine with a storage capacity of 1 to 30 tons of bullets and an adjustable bullet charging rate, enjoys the capability to count the number of bullets fed to the mill, adjust the time intervals and the number of bullets to be fed to the mill, and separate bullets with a diameter of 25 to 125 mm and higher,” said Mohammad Dourali, a faculty member of Sharif University of Technology.

“Also, the device has a user interface for the operator to command and it can report the amount of bullets consumed, the amount of bullets in the tank, charge history and record amounts,” he added.

“Continuous charging of pellets in the mill is an alternative to the traditional method of manual charging, which increases the productivity of the mill, reduces fluctuations in the engine power and impact of the mill, decreases the required manpower and equipment, and records the history and a detailed report on the amount of charging,” Dourali said.

4155/v