Nano-Based Flux-Cored Wire Produced in Iran

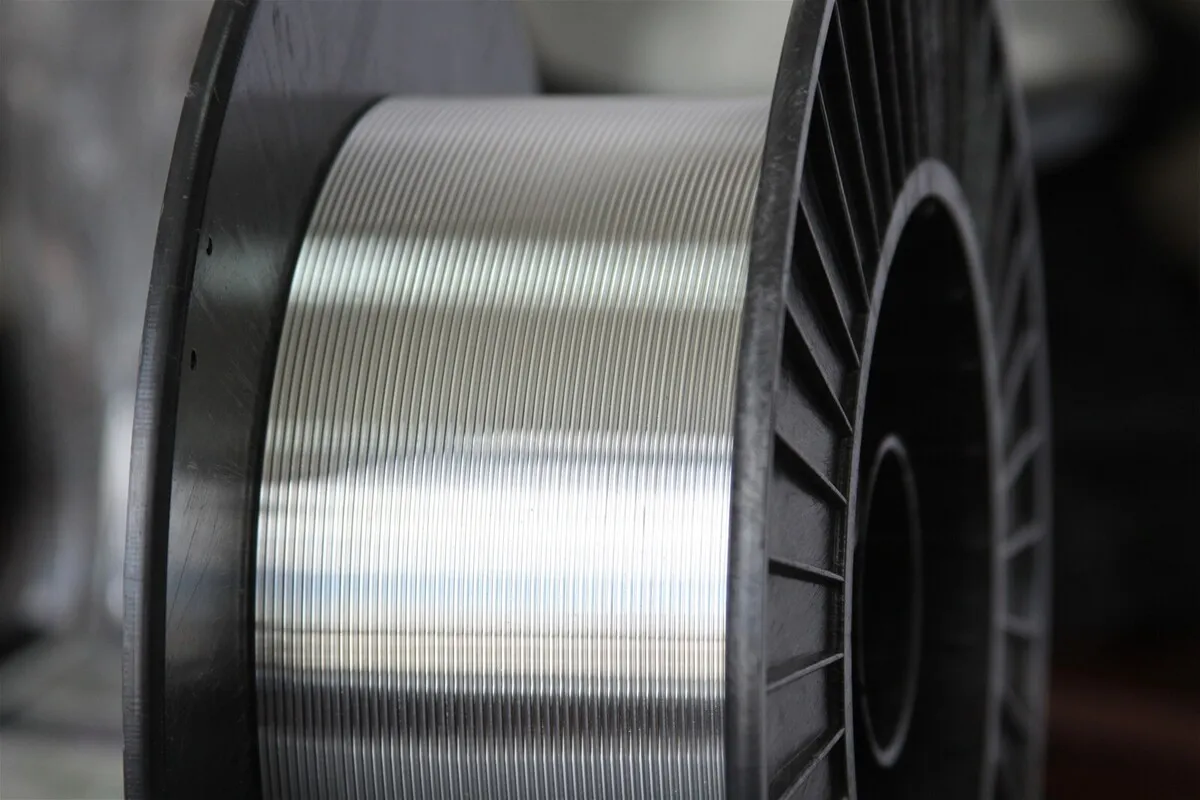

‘Nanostructured Advanced Materials Technologies Development (Namad Co.)’ company produced the flux-cored wire which can deposit a thin film of hard alloying materials with nanometric phases on the external surfaces of steel instruments requiring high wear resistance.

While fabricated in the form of a cylindrical metal sheath and filled with different alloying elements, the formation of oxide nanoparticles in this product has resulted in improved wear resistance of formed coating.

The product can be used for deposition of a hard coating on instruments, reconstruction or repairing of hard coatings on instruments and deposition of a hard coating on the devices which require high wear resistance in mining industry.

Earlier, in May, a technological company in Iran had also succeeded in replacing copper with nanomaterials in making welding electrodes to decrease environmental hazards.

“By using these nanomaterials instead of copper, there is no need for an acidic bath and compounds, therefore, the risk of acid evaporation in the environment will be zero,” said Mohammad Reza Afkhami, the chairman of the board of directors of the company.

“Also, in common electrodes, a lot of water is needed, and with this replacement, water consumption has reduced,” he added.

Noting that the company’s experts have made lots of efforts to replace copper with different materials to decrease costs and minimize the negative environmental impacts, Afkhami said, “We have succeeded in increasing efficiency by 50% with this new technology.”

"We have also managed to enter the European markets in the past few years and exported 24 tons of electrodes to Spain. We are currently exporting our products to neighboring countries including Georgia," he concluded.

4155/v