Iranian Inventor Makes Automatic Overdrive Gearbox to Shift Gear Immediately

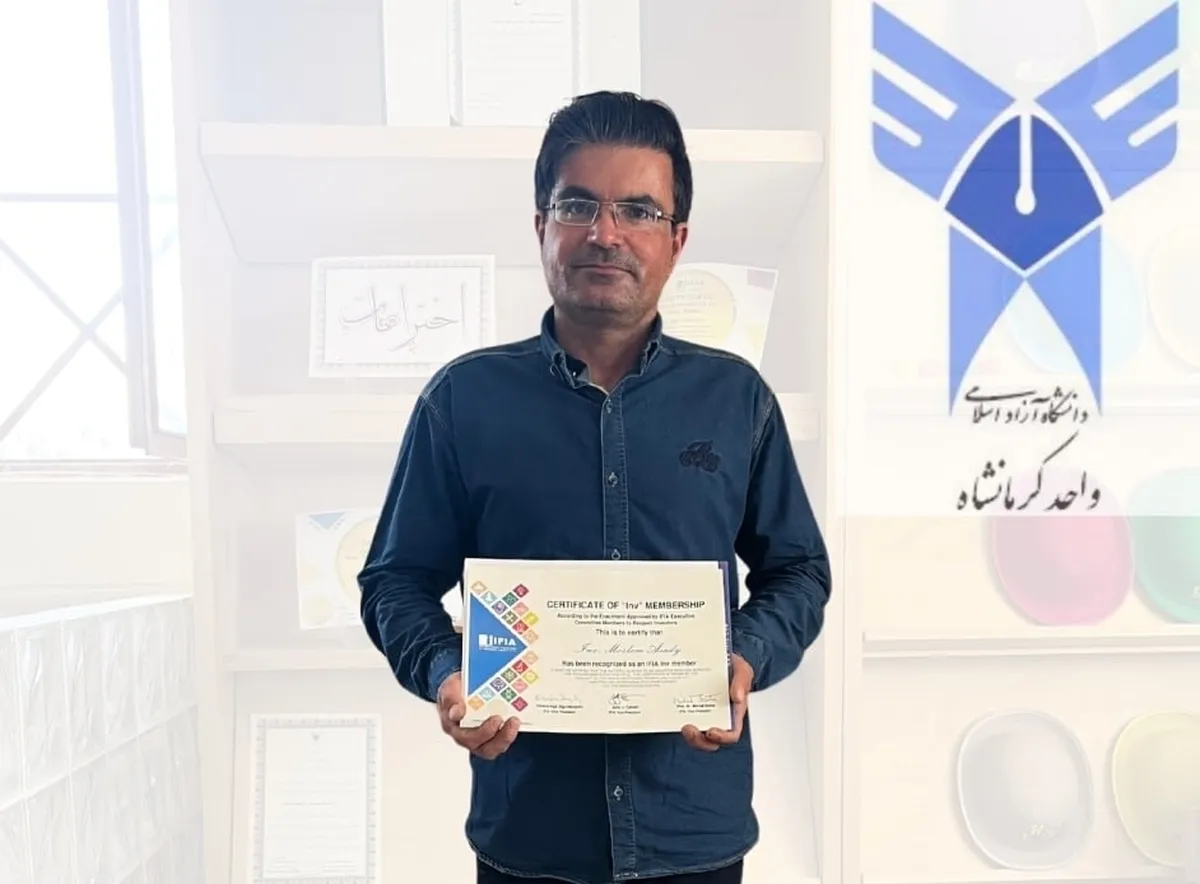

Moslem Assadi, the managing director of Bakhtar Gearbox Makers company, stationed at the incubator center of Islamic Azad University’s Kermanshah branch, presented his technological idea titled ‘automatic overdrive gearbox for heavy vehicles and won the honor medal of INV from the International Federation of Inventors' Associations.

“The device we designed is related to the Zf heavy vehicle gearbox in Germany. These gearboxes are one of the most high-quality gearboxes in the world and can be installed on all types of cars of the Benz Myler, Iveco, Volvo, etc. and they are known as overdrive among the users in the world,” Assadi told ANA.

“The way it works is that in heavy cars, unlike passenger cars, due to the high weight of the car, the car accelerates slowly when shifting gears, and in the zf design gearbox and the front part of the shaft, an additional gear is installed, which is forward and backward by the overdrive system,” he added.

“In addition, the overdrive system reduces excessive pressure on the bearings and prevents the so-called dead gear phenomenon,” Assadi said.

In a relevant development last year, Iranian researchers at Amirkabir University of Technology in Tehran had developed techniques to detect different defects simultaneously in spiral gears based on vibration and sound signal.

Hassan Alavi, PhD student at Amirkabir University of Technology’s Faculty of Mechanical Engineering and executive director of the "simultaneous detection of defects in helical gears based on vibration and sound signal processing" project, said that early detection of faults in machinery matters a lot as it reduces maintenance and repair costs considerably.

“Several faults usually appear simultaneously in machines. Many researches have been done to detect only one defect, but there are few researches in the field of simultaneous defects detection,” Alavi said, according to the public relations department of Amirkabir University of Technology.

“In this research, new methods for identifying and classifying faults at the same time were proposed and they were evaluated from both theoretical and experimental perspectives. These proposed methods perform better as compared to previous methods,” he continued.

“In this project, the use of sound signal from the machine was studied in fault detection. since the measurement and recording of signal is simple and accessible, sound-based fault detection makes the fault detection process easier," the researcher said.

“In this research, theoretical simulations and, in parallel, extensive experimental tests were used in the acoustic research laboratory of the Mechanical Engineering Faculty of Amirkabir University of Technology to find out the effect of defects on the vibration and sound signal produced by the gearbox,” Alavi added.

According to him, in the end, creative techniques to separate the symptoms of simultaneous defects and new methods in the field of artificial intelligence, which are known as deep learning, have been used to classify the type and severity of defects.

4155/v