Iranian Company Produces Nano-Based Additive for Rapid Heat Exchange

Azma Sanjesh company manufactured the additive which increases the speed of heat exchange and brings advantages like preventing corrosion and increasing the life of equipment in industry.

"We have produced a nano additive to improve heat transfer properties in gas industry converters which is currently used in 28 companies,” said Abdolrahim Sabouri, the managing director of the company.

“This additive has specially been produced for closed systems like chillers and boilers, and it can be used for both heating and cooling systems,” he added.

“The results showed that the nano additive can result in a 15% to 25% improvement in heat transfer. It increases the speed of heat transfer, creates anti-corrosion properties in facilities and boosts the life of equipment and infrastructure. Another feature of this product is its high stability,” Sabouri said.

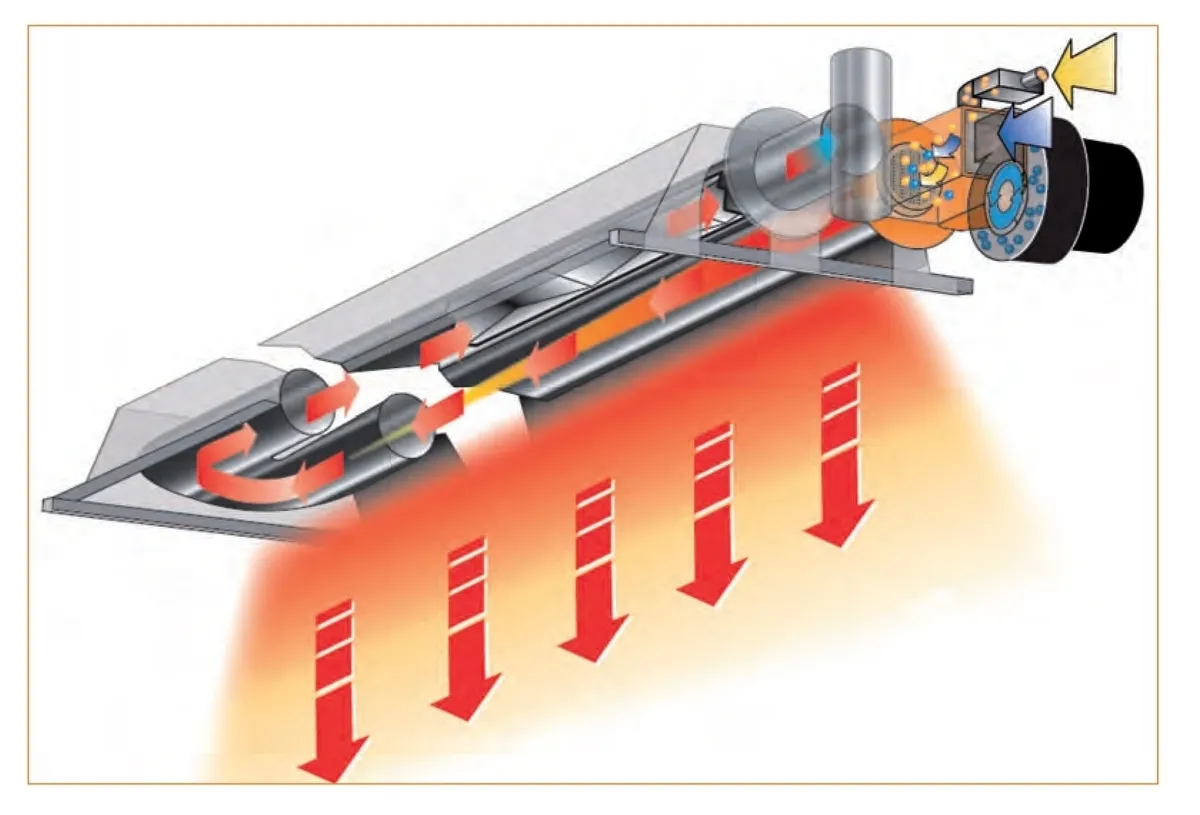

In a relevant development in August, specialists at an Iranian company also utilized ceramic nanoparticles to manufacture a radiant heater with minimized CO emission.

‘Beh Faravaran Novin Aria Sarmad’ company made the radiant heater in which a metallic catalyst-containing layer is deposited on ceramic nanofibers. The surface temperature of the product can reach 500 oC and can offer low oxygen consumption and minimized CO and NOx emission.

Applying a nanometric catalytic layer on the fiber has resulted in more efficient combustion.

The radiant heater can be used for drying the insulating paint applied on cables and wires, thermo-forming (deformation by heating), drying the painted glass, preheating the textile products, oil and gas industries (heating hoses in the petrochemical complex), heating the industrial environments, drying the printing ink and environments with flammable gas.

4155/v