Ceramic Nanoparticles Used by Iranian Experts to Produce Radiant Heater

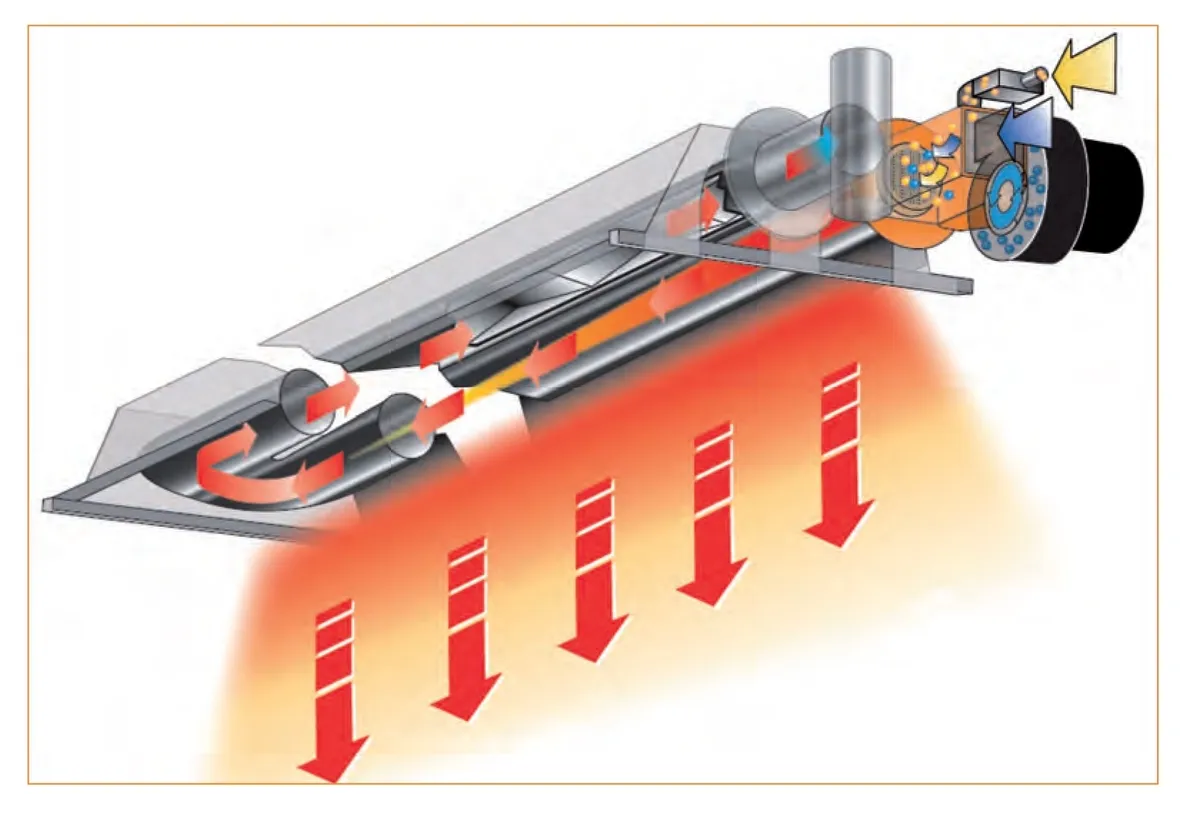

‘Beh Faravaran Novin Aria Sarmad’ company has made the radiant heater in which a metallic catalyst-containing layer is deposited on ceramic nanofibers. The surface temperature of the product can reach 500 oC and can offer low oxygen consumption and minimized CO and NOx emission.

Applying a nanometric catalytic layer on the fiber has resulted in more efficient combustion.

The radiant heater can be used for drying the insulating paint applied on cables and wires, thermo-forming (deformation by heating), drying the painted glass, preheating the textile products, oil and gas industries (heating hoses in the petrochemical complex), heating the industrial environments, drying the printing ink and environments with flammable gas.

Earlier this year, a professor of mechanical engineering faculty of Iran University of Science and Technology had also succeeded in making a cylindrical catalytic radiant heater.

The device, designed and built for the first time by Seyed Mostafa Hossein Alipour, can be utilized in various industrial fields like oil and gas, auto-making, petrochemical, food, pharmaceutical, paint, wood and paper industries, and for environment heating.

The Iran-made catalytic radiant heater is a knowledge-based product which has been designed and manufactured based on nanotechnology.

The system is a good alternative to traditional common heaters (bathroom heaters) which have an efficiency of about 30%. The new system is installed directly on the gas transmission line and enjoys an efficiency is more than twice that of bathroom heaters.

4155/v