Top News of Last Week with ANA

Azad News Agency (ANA) published a number of scientific and technological news during the past week whose top ones are as follows:

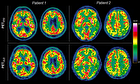

Iranian Scientists Use Nanotechnology to Treat Cancer

Iranian researchers at a knowledge-based company produced a new and cost-effective nanomedicine for treating cancer patients.

“This drug plays an important role as an anti-tumor drug in the treatment of certain types of cancer and is used in the treatment of metastatic breast cancer, specially for the patients who have heart problems,” said Ahmad Pourahadi, the managing director of the company.

“The drug’s name is Sina Doxosome and it is also effective in the treatment of advanced ovarian cancer and acts as an important treatment option in reducing the growth and spread of cancer cells,” he added.

Noting that the drug is also applied as an effective solution in the treatment of Kaposi's sarcoma in patients with AIDS, Pourahadi said, “This product contains a drug that can selectively destroy cancer cells. The doxorubicin hydrochloride contained in this drug is surrounded by small liposomal spherical shells.”

“The concentration process in this drug allows the drug to be more effectively directed through the bloodstream to cancerous tissues,” he underlined.

Iranian Firm Produces Eco-Friendly Starch-Based Disposable Containers

Iranian researchers at a knowledge-based company added special nanoparticles to starch to accelerate and improve the biodegradability process of plastics.

“Our company produces various types of biodegradable additives for plastic bags, disposable containers, and toys. Our nano-additives are designed to accelerate and improve the biodegradability process of plastics,” Hirsa Jouya, the managing director of the technological company that produces different types of biodegradable additives, told ANA.

Noting that one of the special products of the company is designed for starch-based disposable containers, he said, “Unfortunately, many of the plant-based disposable containers produced in Iran are not manufactured according to the required standards. The standard says that these containers should contain 70% starch and 30% polypropylene, but in practice, this ratio is reversed and 70% polypropylene and 30% starch are used in their manufacture. This makes these containers practically not biodegradable.”

“The products we have designed help manufacturers of these containers to significantly reduce the amount of polypropylene and even bring it to zero, while maintaining the qualities of these containers like mechanical strength, thermal stability and ultimate strength,” Jouya said.

Iranian Experts Produce Protective Coatings for Oil Pipes

Iranian researchers succeeded in production of new coatings for oil and gas pipelines which are based on epoxy and polyurethane resin.

Protective coatings based on polymers are used to maintain and protect metal structures against corrosion in corrosive environments. These composite coatings consist of pigments, fillers, organic and inorganic polymer resins, organic solvents, and also special additives.

Depending on the use and application of each type of these coatings, their ingredients and percentage composition will be different. Also, the goals required for each organic coating are different.

The specific use of types of pigments and fillers in organic coatings is very important with respect to Pigment Volume Concentration, and their preparation with respect to the lower or higher amount of PVC can affect the permeability, physical, mechanical properties, and chemical resistance. These coatings can consist of several layers and the use of inorganic or organic polymer resins has significant effects on the quality of the organic coating.

The type of organic resin and its amount affect the adhesive or cohesive properties, rheological properties, uniformity, gloss, and electrochemical properties of the formed film. Also, the formation of the film as a thermoset or thermoplastic changes the performance of the organic coating on the quality and performance.

Iran-Made Knowledge-Based Products Showcased at 12th Iran Airshow 2024

Several Iran-made knowledge-based products were displayed at the 12th Iran Airshow 2024 exhibition held on Kish Island in the Persian Gulf.

The Iran Airshow 2024, which was held with the support of the Innovation and Prosperity Fund on December 10 to 13, is considered as one of the largest events in the aviation and aerospace industry.

In the pavilion dedicated to knowledge-based companies in this exhibition, 15 Iranian knowledge-based companies presented their products and demonstrated their export capabilities in the field of the aviation industry.

The products displayed in the pavilion included ASR Green De-Ice, Black Box Crash Enclosure, Flight Data Monitoring (FDM) and Aircraft Engine Condition Monitoring (ECTM), Polysulfide Sealant, Jet Starter Hose, Design and Production of 8-Passenger Commercial Jet Aircraft, Digital Compass µsPOINT, Tianwan 3D Printer (SLS), Providing Aircraft Repair and Maintenance Services, Autonomous Navigation System, 400Hz Inverter, Turbine Blades and Aircraft Engine Parts, Heavy Cargo/Agricultural Intelligent Drone, Airport Runway Visual Navigation Assistance System, and GPS Independent Visual Navigation System.

Given that the Iranian products presented at the fair were of high quality, organizers and dispatchers negotiated with other countries, including India and France, to develop technologies available in specialized areas of simulation or virtual reality and aerospace.

Official: 5% of Iran’s Exports Belongs to Knowledge-Based Products

The products made by the Iranian knowledge-based companies accounted for 5% of the country’s exports share in the past Persian calendar year (ended on March 19), an official said.

Head of the Trade Promotion Organization of Iran Mohammad Ali Dehqan Dehnavi made the remarks, saying that the products exported by the knowledge-based companies made up of 2.6 percent and 5 percent of the country’s exports share in weight and value, respectively compared to a year earlier.

He added that the exports of non-oil commodities, especially exports relying upon the knowledge-based economy, play an important role in the country’s economic security and development.

In contrast, dependency of exports and economy on the oil sales, semi-finished materials is one of the weak points of the country especially during the sanctions period and international restrictions, Dehqan Dehnavi underlined.

Undoubtedly, at present, the knowledge-based and technological companies are considered as one of the leading components in spurring export of the country, he said.

Iran Starts Mass Production of National Train Wagons

The mass production line of the National Train started in Tehran Wagon Manufacturing Company in a ceremony participated by senior Iranian officials.

The National Train Set Project, which was initiated in 2019, aims to indigenize metro technology and reduce import dependency. Developed through a collaboration between the Iranian Vice-Presidency for Science and Technology and Knowledge-Based Economy, Tehran Municipality, and knowledge-based companies, the project achieved 85% indigenization of components, including critical systems like bogie technology.

The first operational train was manufactured in 2022 and successfully passed safety tests. Currently, the train is in service on metro lines such as Tehran’s Parand line. A contract for producing 113 additional carriages is underway, with two more train sets expected to join Tehran’s fleet by late 2025.

This initiative not only strengthens local industries but also reduces foreign exchange costs and enhances the quality of urban transportation. The project received significant financial backing, with $30 million allocated alongside municipal contributions to advance its mass production.

Radar-Absorbing Composites Produced by Iranian Scientists

Iranian researchers at the Islamic Azad University’s Karaj branch succeeded in designing and manufacturing radar absorbing composites (in the X-band, frequency 4.8 to 4.12 GHz).

Today, the increasing spread of electromagnetic waves (specially at frequencies above one GHz, which are referred to as microwave waves) due to military, telecommunications, and electronic applications has led to a lot of research being conducted on the negative effects of these waves on the performance of electronic and telecommunications equipment. One way to prevent the negative effects of waves is to apply protective coatings. Absorbent composite coatings are a suitable alternative to other radar-evading materials due to their electrical properties, low density, high strength, and reasonable price.

These composites, considering the nature of electromagnetic waves, which propagate over time and distances like a flat wave and have electric and magnetic fields perpendicular to the direction of propagation, should have two main absorbing electric and magnetic components.

In these composites, a type of home-made epoxy with a reasonable price and sponge iron powder particles have been used as electrical and magnetic absorbers, respectively. What makes this product preferable compared to other similar products is the iron powder reinforcement with a sponge and porous morphology which has been produced for the first time in Iran by the solid-state reduction method.

Radar absorbing materials (RAMs) are dielectric or magnetic materials that has capacity for absorbing electromagnetic waves. In order to increase frequency range (bandwidth) of the absorbance, several structures have been already proposed by several researchers.

Iranian Experts Make Oil Centrifuges, Other Lab Equipment

Iranian researchers at a technological company took an important step in reducing dependence on foreign states by designing and manufacturing advanced laboratory equipment and oil centrifuges.

“Our main field of research is the design and manufacture of general laboratory equipment. Our products are used in fields like food, petrochemicals, textiles, paints and resins,” said Farid Monzavi, the managing director of the knowledge-based company.

“In the food industry laboratories section, we have been able to design and manufacture general devices, including incubators, various ovens and equipment related to chemical and microbial laboratories,” he added.

Monzavi also described the production of laboratory equipment in the textile sector as another field of activity of the company, and said, “Humidity chambers for conducting environmental condition tests are among our achievements in this field.”

“The production of devices like paint and resin mixers, temperature and humidity test chambers, and centrifuges for the oil industry is another success of this company in the petrochemical field,” he noted.

Iranian Scientists Produce Air Track System for Physics Tests

Iranian researchers at a company which produces laboratory equipment succeeded in building an air track device which enjoys high quality and accuracy.

“We are active in the field of building physics laboratory equipment, including the basic one and two topics, and we have gained more than 30 years of experience in this field,” said Ali Mohammad Khaleqi, the production manager of the company.

“The air track device is one of our products that is used in the field of basic two physics to analyze collisions and its relationship with physics formulas and it enjoys high accuracy and unique efficiency,” he added.

“Last year, we were able to sign a contract with Al-Zahra University to sell the air track system,” Khaleqi said.

An air track is a scientific device used to study motion in a low friction environment. Its name comes from its structure: air is pumped through a hollow track with fine holes all along the track that allows specially fitted air track cars to glide relatively friction-free. Air tracks are usually triangular in cross-section. Carts which have a triangular base and fit neatly on to the top of the track are used to study motion in low friction environments.

Iranian Knowledge-Based Company Produces Fresh Water with Solar Power

A knowledge-based company has succeeded in designing and building a portable solar water desalination device.

“Our knowledge-based company has succeeded in designing and building a portable solar water purifier which can float on seawater, salt water, or even collected rainwater and it effectively absorbs sunlight and converts it into heat,” Farzaneh Heshmati, one of the company's researchers from Tarbiat Modarres University, told ANA.

Noting that the device maximizes the rate of water evaporation and condenses and collects the purified water by using a special technology, he said, “The final output of the device is fresh and germ-free water that is completely disinfected and suitable for drinking.”

“This device is completely solar and does not require electrical energy or moving parts like a pump to operate,” Heshmati said.

Iranian Knowledge-Based Company Makes Spray Dryer for Different Industries

An Iranian knowledge-based company produced spray drying systems to convert liquids into powder for use in the pharmaceutical, nanotechnology, and food industries.

“Reactor, spray dryer and extruder are among the products that are designed and produced by the researchers of our company. These devices are in the category of advanced technologies,” Khosro Malek Khosravi, the managing director of the company.

Noting that the devices produced in this company are widely used in advanced industries, specially in the pharmaceutical sector, he said, “Our spray dryer is the main tool for researchers to conduct detailed research and achieve advanced formulations.”

“The spray dryer turns liquids into powder and has wide applications in the pharmaceutical industry, nanotechnology industry, food industry (like milk powder production) and other moisture sensitive industries,” Malek Khosravi said.

Iranian Experts Manufacture V-Shaped Blenders for Oil Industry

Iranian engineers at a technological company succeeded in designing and manufacturing V-shaped blenders which can fully mix two materials in oil industry.

“The design and production of physics laboratory equipment is one of our main research fields. Besides that, we have also designed and manufactured laboratory equipment for the oil industry,” said Ramin Siami, one of the researchers of the company.

He referred to the latest achievement of this company, i.e. V-shaped blenders, and stated, “These devices are made in different capacities from 5 liters and 10 liters to 100 liters and more, and they have a special ability to mix powder materials that are difficult to combine with normal methods.”

“This device completes the mixing process with successive taps in two clockwise and counterclockwise directions. The desired materials enter the V-shaped cylinders of this blender and collide with each other with continuous blows and are completely mixed in a certain period of time,” Siami added.

“The special features of these mixers, like the V-shaped design and precise operation, have caused these devices to be used as one of the advanced laboratory equipment in various fields, including the oil industry and other related industries,” he said.

Iranian Specialist Invents Environmentally-Friendly Concrete to Reduce Pollutants by 50%

A faculty member of Islamic Azad University succeeded in designing and implementing a type of environmentally-friendly concrete that reduces pollutants by 50% and is 30% cheaper compared to other samples.

“This type of cement reaches its ultimate strength much faster than Portland cement and inherently has much lower permeability than Portland cement in the early stages; however, calcium aluminate cement, despite its good qualities, has two very key shortcomings that have caused the use of this cement in by engineers to be very low,” Alireza Rasekhi, a faculty member of the Civil Engineering department of Islamic Azad University’s Qeshm branch, told ANA.

“The first problem with this cement is that after a while, a transformation phenomenon occurs in it, which causes a sudden decrease in strength and, as a result, durability in concrete made with calcium aluminate cement, which is a very big drawback and, in addition, it is many times more expensive than ordinary cement,” he added.

“The result of our research was the production of a mixed calcium aluminate cement, which has three key advantages over previous cements. First, its technical specifications and durability have been greatly improved. Second, it is about 30% cheaper than a similar sample, and third, it reduces environmental pollution by about 50%, making it a green or environmentally friendly product,” Rasekhi said.

Home-Made Vacuum Distillation Device Unveiled in Iran

A vacuum distillation device manufactured by an Iranian knowledge-based company for qualitative assessment of energy products was unveiled in the presence of the country’s economy minister and other officials.

“This product is made for qualitative measurement of heavy oil products like crude oil, fuel oil, base oil and some industrial oils,” said Moslem Mashayekhi, the managing director of the knowledge-based company.

“This knowledge-based product is used to determine the boiling range of products, according to the ESTM D1160 standard and is equivalent to the Iranian standard 8908. It is completely indigenous and is used in the oil and energy industry,” he added.

Noting that at present the device has been commercialized and several devices have been sold, Mashayekhi said, “There is a good market for this product in the region and the Persian Gulf countries, and we hope to receive support for exporting this device to countries that are active in the oil, gas and energy sectors.”

He explained that vacuum distillation is one of the best laboratory and industrial methods used to separate substances in liquid solutions, saying, “In this method, the desired solution is placed under vacuum, which lowers the temperature of the solution. As a result, the dissolved substances can be separated from each other with less energy.”

“Using the vacuum distillation method is suitable for solutions in which the substances in them have a high evaporation temperature and also a high boiling point in the atmosphere,” Mashayekhi added.

4155/v