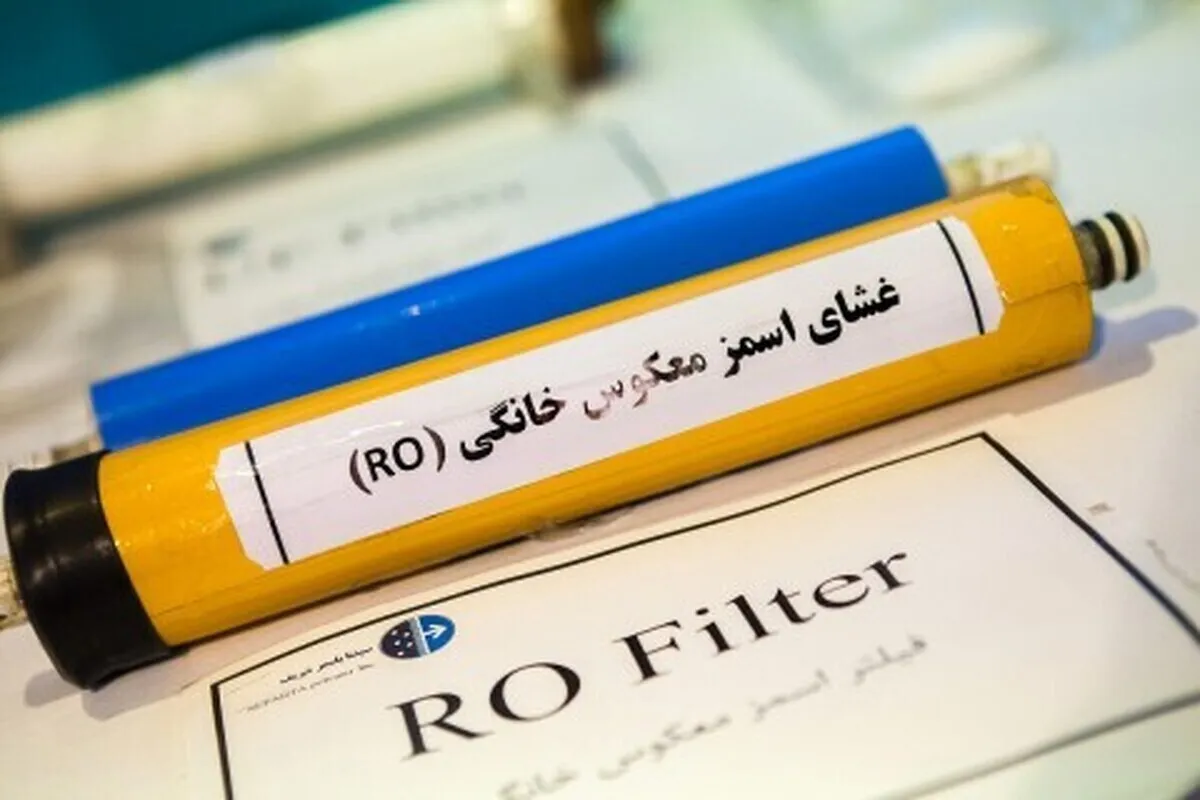

Leachate Filter Produced in Iran by Using Nano Membranes

“I have not seen a company that has offered a similar product to our customers, of course there are some products like reverse osmosis devices and water softeners that are produced in a number of companies, but they are not able to perform separation, processing, or purification of industrial and complex wastewaters by using membranes,” said Sina Maleki, the founder of the knowledge-based company.

“It took almost 10 years to pave this path. At first, we focused on production of membranes, and then made specialized membranes, and now we also provide services to large factories,” he added.

“Our product and a US-made sample were tested by a costumer in the same time. The consumer preferred to approve our product based on engineering data,” Maleki said.

In a relevant development in April, Iranian researchers at Islamic Azad University had also succeeded in patenting a device for treating waste leachate with advantages like the use of low-cost materials in preparation of absorbent filters, the simplicity of the treatment process, and the absence of waste.

Hamidreza Tousi, a student at Shahid Beheshti University and a member of the faculty of Chemistry of the Islamic Azad University, Qa’emshahr branch, and Morteza Ra’yati, a member of the Faculty of Civil Engineering of the university, succeeded in patenting the leachate treatment device.

The municipalities, as the custodians of urban waste collection and waste management, are parties to any possible contract for purchasing the device.

“The device consists of four parts of disinfection, settling of suspended pollution, surface absorption and filtration, and one of its features is the use of cheap materials in preparation of absorption filters which are all available in Iran,” Tousi told ANA.

He described another advantage of the leachate treatment device as the simplicity of treatment process and the absence of waste production, saying, “In the disinfection part, all pathogens and disease-causing agents are destroyed, and then sedimentary materials are removed from the solution stream by using filters made of mineral pumice.”

“In the next step, the remaining substances in the leachate are separated from the solution with the help of activated carbon filters, ultrafiltration and RO, and the purified water meets the environmental standards necessary for use in agricultural sector and discharge into the surface waters,” Tousi said.

4155/v