Production of Nano-Based Brake Pad Adhesive in Iran with High Thermal Resistance

‘Polymer Pishrafteh Amirkabir’ company has succeeded in producing the brake pad adhesive in which nanoparticles are used to improve quality.

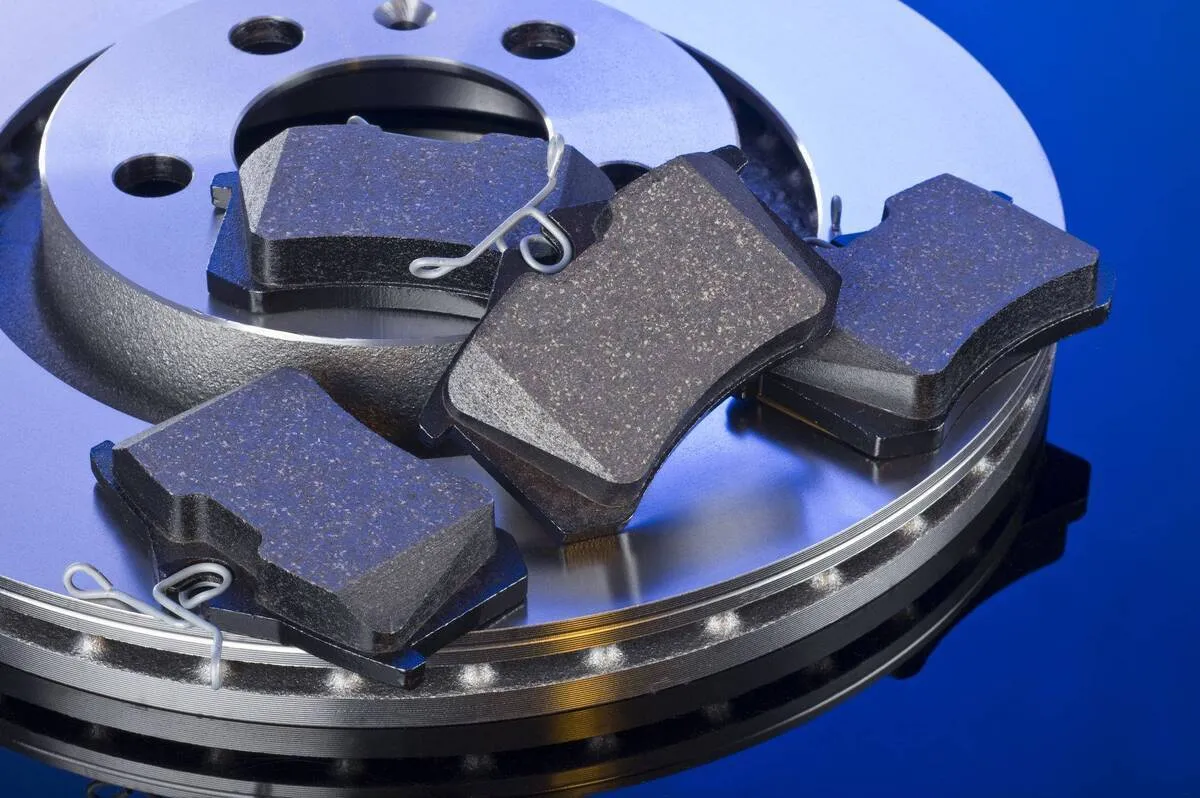

"Pad adhesive is used in the production line of brake pads for light and heavy vehicles whose task is to connect the two lower parts and the upper layer of the pad to each other,” said Mohammad Alizadeh, one of the founders of the company.

“We used nanoparticles to improve the thermal properties of this adhesive. The pad is a piece which is constantly subjected to friction and high temperature,” he added.

Noting that the addition of nanoparticles to the adhesive increased the thermal resistance of the pad so that it shows more resistance than normal pads in the hot shear test, Alizadeh said, “At present, the adhesive is being produced on an industrial scale of one ton per month.”

In a relevant development in July, experts at an Iranian nanotechnology firm had also succeeded in manufacturing a new type of reinforcing adhesive which can be used for car body.

‘Ayegh Khodro Toos’ company has made the product which is an epoxy resin-based and solvent-free reinforcing adhesive containing nanoparticles.

It should be cured at temperatures above 140 C to become resistant against moisture, heat, extreme cold, and acidic and alkaline media.

The incorporation of nanoparticles in the epoxy resin matrix has resulted in improved flowability, adhesion strength, and heat flux, and enhanced wear resistance in a convenient and cost-effective way.

The product can be used as reinforcing adhesive for ceilings, doors, columns, and backs of the car.

4155/v