Anti-Spatter Solution Made by Iranian Nanotechnology Firm

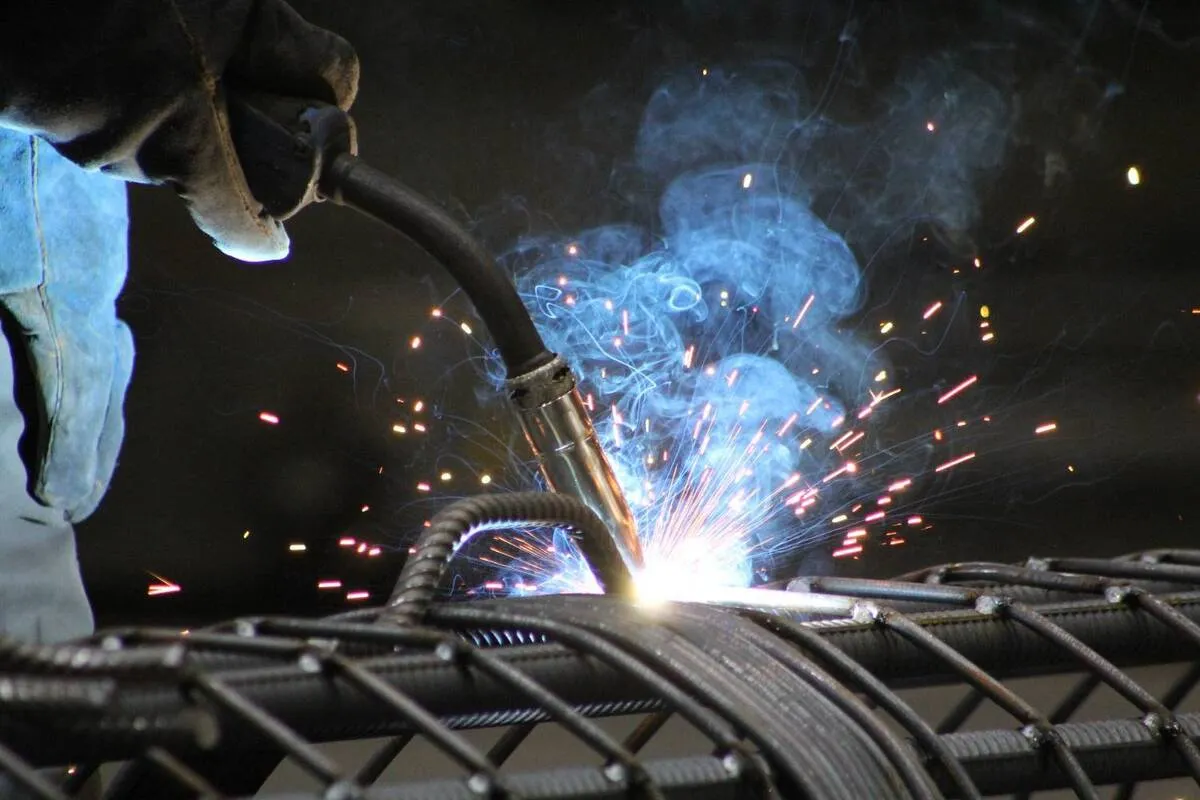

‘Parto Behtab Shimi Alborz’ company produced the nanoparticle-containing solution which can be applied on the metallic parts before welding.

It can form a protective layer on its underlying substrate and prevent the adhesion of sparks and molten drops spattering around.

Applying a thin layer of the nanoparticle-containing solution on the welding part results in emerging the anti-spatter property in welding and decreasing the interfacial adhesion between welding-arisen molten drops and exterior surfaces of welded part.

The solution can prevent unwanted spatters to adhere to surrounding parts.

In a relevant development in May, a technological company in Iran had succeeded in replacing copper with nanomaterials in making welding electrodes to decrease environmental hazards.

“By using these nanomaterials instead of copper, there is no need for an acidic bath and compounds, therefore, the risk of acid evaporation in the environment will be zero,” said Mohammad Reza Afkhami, the chairman of the board of directors of the company.

“Also, in common electrodes, a lot of water is needed, and with this replacement, water consumption has reduced,” he added.

Noting that the company’s experts have made lots of efforts to replace copper with different materials to decrease costs and minimize the negative environmental impacts, Afkhami said, “We have succeeded in increasing efficiency by 50% with this new technology.”

"We have also managed to enter the European markets in the past few years and exported 24 tons of electrodes to Spain. We are currently exporting our products to neighboring countries including Georgia," he concluded.

4155/v