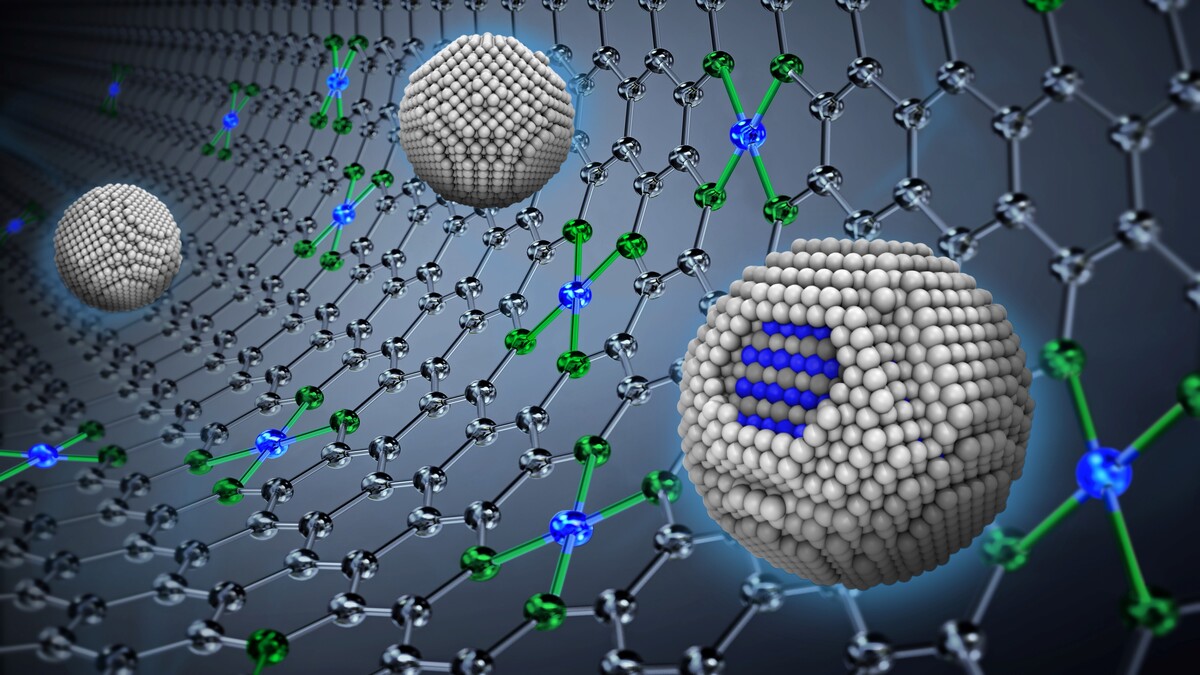

Iranian Researchers Produce a Multi-Component Oxide Catalyst Using Spray Pyrolysis Method

“The purpose of implementing this project was to produce a catalyst with a new composition (oxide catalysts containing lanthanum, nickel and manganese) in a new way (spray pyrolysis method),” said Amirhossein Shahnazi, a graduate from the Tehran-based Amirkabir University of Technology (AUT )and the executive director of the project "Studying Spray Pyrolysis Process Variables and Chemical Composition on the Morphology and Catalytic Properties Of Perovskite in the Methane Reforming Process," which was carried out under the supervision of Sadegh Firouzi, a professor at the highly prestigious university, according to AUT public relations department.

According to the researcher, this production method has led to an improvement in the physical and chemical properties of the catalyst such as its efficiency and an increase in its lifespan.

“This method is based on results of a research done by one of the AUT's PhD graduates under the title of ‘production of nickel catalysts based on alumina’. Finally, the research led to the production of multi-component oxide catalysts containing lanthanum, nickel and manganese elements," he further said.

Shahnazi noted that for the industrialization of their project, it seems that we have a long way ahead because this research is based on the use of rare soil components, which are still not available in the industry due to their scarcity and high expenses.

“The method of producing catalysts, their chemical composition and their microstructural properties are among innovative scientific contributions, findings of which have been published in several articles in scietific journals,” he further said.

“Continuity in production and uniformity in terms of the chemical composition of the product, specific surface of the product, resistance against carbon deposition, which is harmful in the methane reforming process, and its formation on the surface of catalysts, are among the features of this method,” the AUT researcher also explained.

Shahnazi noted that their product has no similar domestic or foreign rival, adding, “These catalysts are highly competitive against the other catalysts that are currently available in the market.”

He concluded that their achievement could be used in the steelmaking (iron revival units) and petrochemical industry to produce heavy hydrocarbons.

4155/i