Iranian Knowledge-Based Firm Manufactures JHDI/Q4 Coating Machine

According to a report by Iran’s National Nano Headquarters, Hassan Jahdi, the executive chief of the project to produce JHDI/Q4 coating machine at the Iranian knowledge-based company said that their firm has focused its activity on manufacturing coating equipment and providing coating services on ultra-hard surfaces using PVD method.

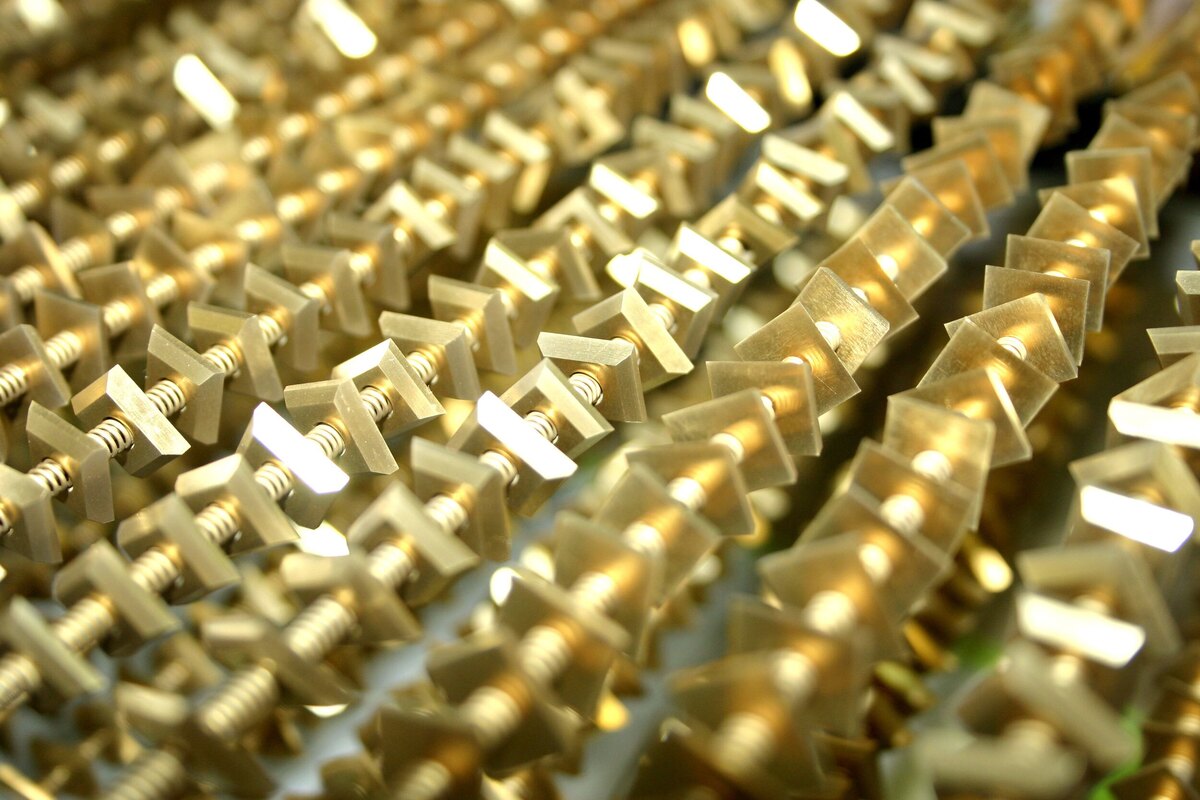

“Our JHDI/Q4 coating machine is used for coating ultra-hard compounds in order to use it in hardware and tools. This technology provides the possibility of creating different combinations on different structures,” Jahdi said.

"There are some other compounds such as carbon, composite, metal and even diamond-like structures whose surface can be coated with this technology," he said, adding, "We used the fourth generation of cathodes in this device, before this, in the three different generations that we previously produced, cathodes were optimized compared to the previous generation.”

“We are trying to upgrade all modules to make the device, from the vacuum system, O-rings to door hinges. Three data-x-items that are very important to us are vacuum chamber and carousel, cathodes and software,” the managing director of the Iranian firm added.

According to the researcher, the vacuum container has many technical complications that must be taken into account when designing.

“The software of this device was designed in such a way that by using it, zero to one hundred functions of the machine can be automated. This software is able to control the machine system every millisecond,” the managing director of the company added.

He went on to say that their firm provides better after-sales service than European companies, adding that European machines are designed for a few limited types of coating, while the Iranian-made machine is for a variety of coatings.

“The price of our device is 50% lower than the similar foreign model,” Jahdi said.

“In this coating system, between 4 and 12 fourth-generation cathodes are used to achieve the highest coating speed with the ability to control the roughness and structure of the coating, and 304 stainless steel is used in all components of the vacuum system. The software control system is completely automated and process error is minimized and controlled,” the researcher said about other advantages of their coating machine.

The project manager further stated that with their device, ultra-hard nitride, carbide and nitrocarbide single-layer coatings, nanolayer coatings with a thickness of 5 to 50 nm can be done.

“Ultra-hard nanocomposite coatings can be created in an amorphous field using this machine. Also, the diamond-like carbon coating including metal carbide nanocrystals can be coated with this device, the chief executive of the knowledge-based company added.

He pointed to East Asia and Turkey as two target markets for their product.

4155/i